What are the Advantages of Using Panel Cabin Kits?

Introduction: Why Panel Cabin Kits Are Changing the Way We Build

Building a cabin or home is a dream for many—a retreat from busy urban life, a weekend getaway, or even a full-time residence in harmony with nature. However, traditional cabin construction often comes with challenges like extended build times, dependency on skilled labor, and weather-related delays.

This has led more builders and homeowners to consider panel cabin kits—prefabricated components that simplify construction without sacrificing quality or customization.

Panel cabin kits provide a smart, efficient alternative that blends the ease of off-site fabrication with the freedom of on-site assembly. Whether you are a DIY enthusiast or a builder looking for better control over schedules and budgets, these kits offer compelling advantages.

What Are Panel Cabin Kits?

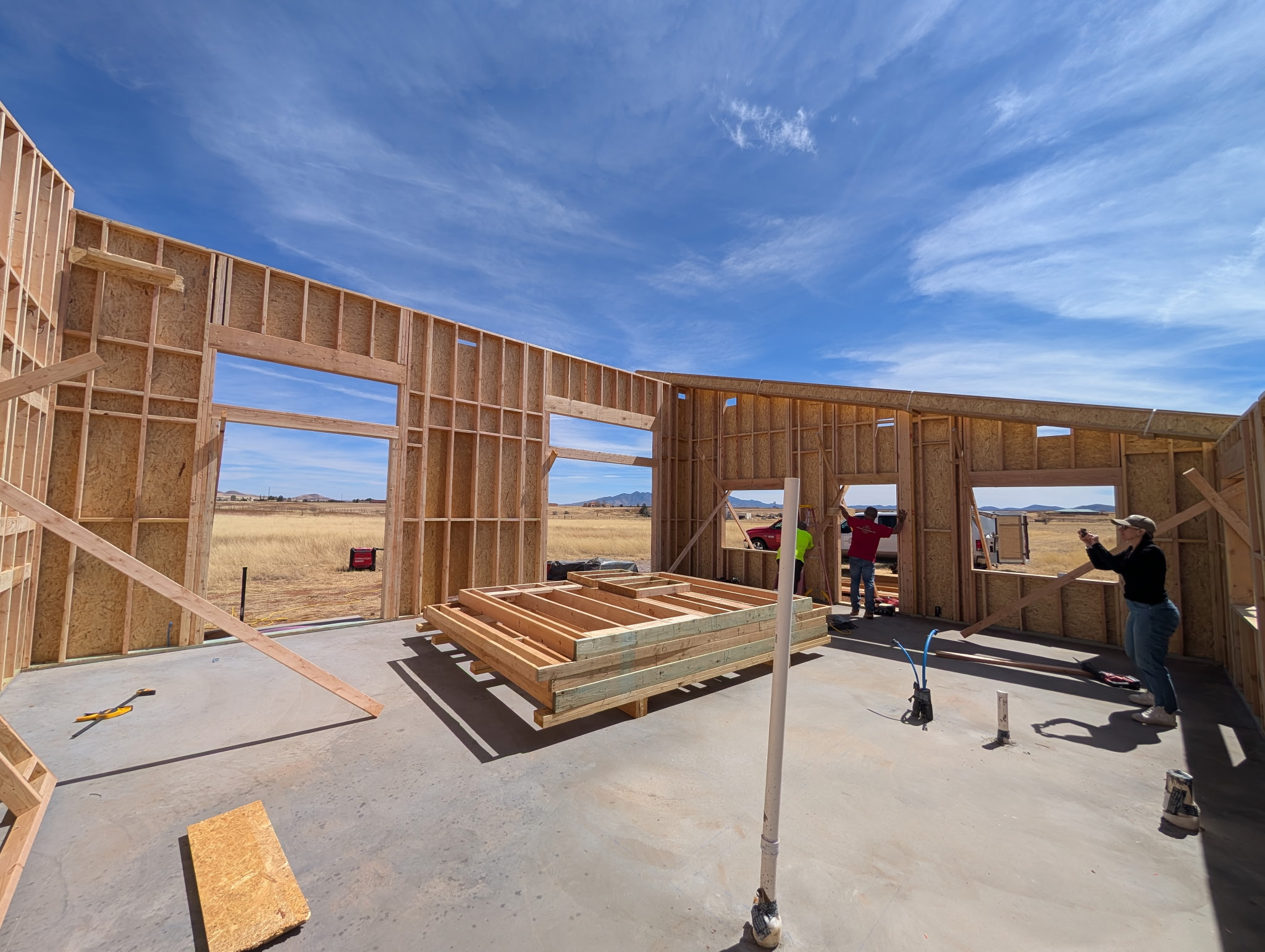

Panel cabin kits consist of pre-manufactured wall panels, floor, and roof trusses produced in controlled factory environments and shipped to the building site for rapid on-site assembly. Instead of building from raw lumber piece by piece, panel kits arrive ready to fit together like a giant, sturdy puzzle.

These panels are made of wood framing with integrated sheathing and insulation, sometimes enhanced with specialty materials for better thermal and structural performance. Once assembled, the panels form the structural shell of the cabin, onto which exterior finishes and interior work are completed.

This approach contrasts with both traditional stick-built construction and volumetric modular homes:

- Stick-built homes rely on framing every piece conventionally at the site, often exposing the project to weather delays and increased labor costs.

- Modular homes are built in large volumetric pieces at factories, shipped whole to sites, limiting some customization and requiring specialized transport.

- Panel cabin kits hit a sweet spot of flexibility, factory precision, and ease of transport.

Faster Construction and Assembly

One of the most significant advantages of panel cabin kits is how dramatically they reduce build times. Because wall panels and floor systems are manufactured off-site in controlled factory conditions, on-site assembly can be completed in a fraction of the traditional build time.

- Factory fabrication is not affected by weather, avoiding on-site delays.

- Panels are pre-manufactured and built to exact dimensions, minimizing on-site adjustments and errors.

- Assembly on-site is streamlined as panels fit together quickly, often like an erector set.

For builders and homeowners alike, this means moving into the cabin weeks or even months earlier.

Superior Quality Control and Precision

Building components in a factory environment leverages automated machinery and precise measurements, giving panel cabin kits a quality advantage over traditional site-built homes.

- Panels are cut square and straight, improving overall fit and finish.

- Quality control checks in factories reduce construction defects and waste.

- Green-R-Panel, for instance, uses AutoCAD layouts and laser cutting technology to ensure panels are consistently accurate.

As a result, cabins assembled from panel kits tend to have tighter seams, stronger joints, and better energy efficiency compared to stick-built projects.

Energy Efficiency and Insulation

Panelized construction inherently supports better insulation and energy conservation:

- Panels can incorporate foam cores or dense insulation tightly sandwiched between framing and sheathing.

- They minimize thermal bridging, which is common in conventional framing where studs conduct heat or cold.

- This leads to lower heating and cooling costs and greater indoor comfort year-round.

Homes and cabins built with panel kits often outperform traditional framed homes on energy bills, aiding sustainability and long-term savings.

Reduced Labor Costs and Skill Requirements

Because much of the heavy lifting—cutting, framing, and assembling panels—is done in the factory, panel cabin kits reduce the demand for skilled on-site carpenters.

- Less framing and measuring on-site translates to fewer man-hours and reduced labor costs.

- Easier and faster assembly means fewer delays and site interruptions.

This is especially valuable in regions where skilled labor shortages have driven up construction costs and caused scheduling challenges.

Customization Flexibility

While volumetric modular homes may limit custom design due to transport constraints, panel cabin kits allow for high levels of architectural flexibility and customization.

- Wall panels, roof trusses, and floor layouts can be tailored to project specifications.

- Add custom window and door openings, modify room dimensions, and personalize finishes on-site.

- Green-R-Panel’s framing systems support one-off designs as well as repeatable builds.

Builders can combine the efficiency of prefab with client-specific designs without the “cookie-cutter” effect sometimes associated with modular homes.

Environmental Sustainability

By minimizing waste and improving energy performance, panel cabin kits contribute to a smaller building carbon footprint:

- Factory fabrication reduces excess material waste typical in on-site cutting and fitting.

- Enhanced insulation reduces lifetime energy usage for heating and cooling.

- Reduced transportation emissions result from shipping compact panels rather than larger modules or multiple deliveries.

This makes panelized construction a more eco-friendly option for the environmentally conscious.

Increased Structural Integrity and Durability

Panelized construction yields stronger, stiffer walls and floors due to engineered design and consistent manufacturing.

- Better load distribution and joint strength improve resistance to high winds and seismic activity.

- Solid panel walls reduce air infiltration and moisture intrusion risks.

- Builders and homeowners can expect longer-lasting structures requiring less maintenance.

Green-R-Panel: An Engaging Possibility for Panel Cabin Kit Builders

For anyone considering panel cabins, Green-R-Panel’s prefabricated framing systems deserve a closer look. Green-R-Panel specializes in panelized wall panels, engineered floor joists, and roof truss systems designed for rapid assembly and precision fit.

Why consider Green-R-Panel?

- Structural shells in 1–2 logical loads: meaning simplified logistics and faster on-site assembly.

- AutoCAD precision manufacturing: panels, floors, and roofs come with engineering support and built-in tolerances for quality and fit.

- Reduced skilled labor requirements: ideal for owner-builders or custom builders facing labor shortages.

- Material versatility: panels are adaptable for cabins, homes, and specialty projects where quality framing matters.

- Sustainability focus: prefabricated panel systems reduce waste, speed up schedule, and improve energy efficiency.

Green-R-Panel empowers homeowners and builders to enjoy the benefits of prefab framing with enough flexibility for custom cabin designs—not a “one-size-fits-all” solution but a smarter, faster path to a personalized retreat.

Frequently Asked Questions About Panel Cabin Kits

Q: Are panel cabin kits only for small cabins?

A: No, panel kits scale from compact cabins to larger homes. The system is adaptable to a variety of building sizes and styles.

Q: Do I need specialized skills to assemble panel cabin kits?

A: Panelized framing simplifies on-site assembly, reducing the need for specialized carpenters. Basic construction skills and following instructions can be sufficient for some projects.

Q: How do panel kits compare to modular homes?

A: Modular homes arrive mostly finished as large modules, limiting transport and customization. Panel kits provide structural shells delivered in pieces, allowing greater design flexibility and easier transport.

Q: Can panel cabins be insulated for cold climates?

A: Yes, panels can incorporate thick, high R-value insulation to ensure good energy performance in all climates.

Conclusion: Why Panel Cabin Kits Make Sense for Your Next Build

Panel cabin kits present a smart, efficient, and environmentally conscious pathway to building your ideal cabin or home. By combining factory precision, rapid on-site assembly, customization freedom, and superior energy performance, panel kits remove many traditional barriers to homebuilding success.

If you seek speed without sacrificing quality—and versatility without modular constraints—panelized construction deserves serious consideration. And with partners like Green-R-Panel, who provide engineered framing systems backed by modern CAD design and quality control, the future of cabin building looks better, faster, and more accessible than ever.

Whether you’re a DIYer dreaming of a weekend getaway or a builder managing multiple projects, panel cabin kits offer an engaging, practical, and compelling building approach.

📞 Ready to explore your cabin build?

Call 1-800-871-7089 or email [email protected] to request a quote or schedule a consultation today.

Comments are closed