Last updated: October 2025

Kentucky’s housing market tells a story of resilience and opportunity. December 2024 sales volume hit $999.48 million—up 8.8% year-over-year—with median prices reaching $265,000, also up 8.8%. Homes sell in just 20 days, three days faster than last year.

The market reveals sustained strength despite inventory challenges. New listings dropped 3.5% to 2,973 homes, while total sales hit 3,270 properties. Kentucky Realtors President Barb Curtis acknowledged the dynamic landscape: “December’s housing market data demonstrates both the resilience and challenges of Kentucky’s real estate market.”

Statewide trends confirm the opportunity. Home prices rose 9.2% year-over-year in January 2025, with the median at $265,000. Inventory increased 10.9% to 13,757 homes, providing buyers more options. Yet with just 4 months of supply and homes spending 57 days on market, Kentucky remains a seller’s market. In September 2025, 17.9% of homes sold above list price.

Construction costs define Kentucky’s competitive positioning. Building ranges from $80 to $220 per square foot in 2025, with most projects averaging $200,000 to $600,000 for Kentucky’s typical 2,500 square foot home. Louisville runs $87-$130 per square foot. Bowling Green commands $120-$220 per square foot depending on quality level. Lexington construction costs $90-$133 per square foot.

Kentucky building costs sit 4% below the national average, making the Bluegrass State attractive for builders and owner-builders. Labor comprises 35-50% of total costs. Construction typically takes 7-12 months using traditional methods.

For custom builders and owner-builders across Kentucky, from Louisville to Lexington, the question becomes: how do you capitalize on Kentucky’s market resilience while managing costs and accelerating timelines?

The answer isn’t traditional prefab homes with their delivery complications through Kentucky’s varied terrain. Strategic Kentucky builders are adopting prefab framing systems—factory-manufactured structural components that arrive ready for efficient assembly while preserving complete design freedom.

Not all prefab approaches deliver equivalent results. Understanding the differences matters for Kentucky’s competitive market.

Complete modular units arrive on trucks. You select from manufacturer catalogs with restricted modifications. Factory scheduling controls timing—expect 4-6 months from order to completion. Quality stays consistent but finish selections are limited. You need crane access and exact foundation work—challenging for many Kentucky properties. Customization gets restricted to pre-approved options. Critical decisions happen during factory production, minimizing your local control over finishes Kentucky buyers expect.

This approach works entirely differently. You receive precision-manufactured structural components—wall panels, floor systems, roof trusses—built to your specifications. Complete design flexibility means any architectural concept works. You control construction timing entirely—critical when competing in Kentucky’s fast-moving market. Precision structural elements arrive with unlimited finish material choices. Standard truck delivery works through Kentucky’s roads. Change finishes, layouts, and systems throughout construction. You maintain complete control over contractors and material sourcing.

The Kentucky advantage? Prefab framing delivers factory precision while you control design, finishes, timing, and contractor relationships—essential for capitalizing on market resilience while managing costs.

Get your free copy of The DIY Owner-Builder’s Step-by-Step Guide to Shell Completion — a simple, practical roadmap to help you plan, frame, and complete your home’s shell with confidence.

Enter your email to download and receive helpful tips, updates, and exclusive insights to keep your project on track.

Kentucky Terrain Complications: Moving oversized modular homes through Kentucky’s varied landscape—from Louisville’s urban grid to rural Appalachian roads—creates serious logistical problems. Many desirable building sites can’t accommodate traditional prefab delivery requirements, especially in established neighborhoods or hillside properties.

Foundation Precision Challenges: Kentucky’s soil conditions vary dramatically across regions. Achieving millimeter-perfect foundations that modular homes demand becomes particularly challenging. One error means expensive delays in a market where homes sell in 20 days and timing determines profitability.

Limited Regional Understanding: Most national prefab manufacturers don’t comprehend Kentucky’s building requirements or regional variations. Your local inspector understands Kentucky—the prefab manufacturer’s team doesn’t.

Cost Reality Beyond Marketing: Advertised pricing excludes Kentucky’s reality: site preparation, utility connections, delivery coordination, crane rentals, customization fees, and permit costs ranging $800-$4,000 depending on location. Final costs frequently exceed quality custom construction alternatives.

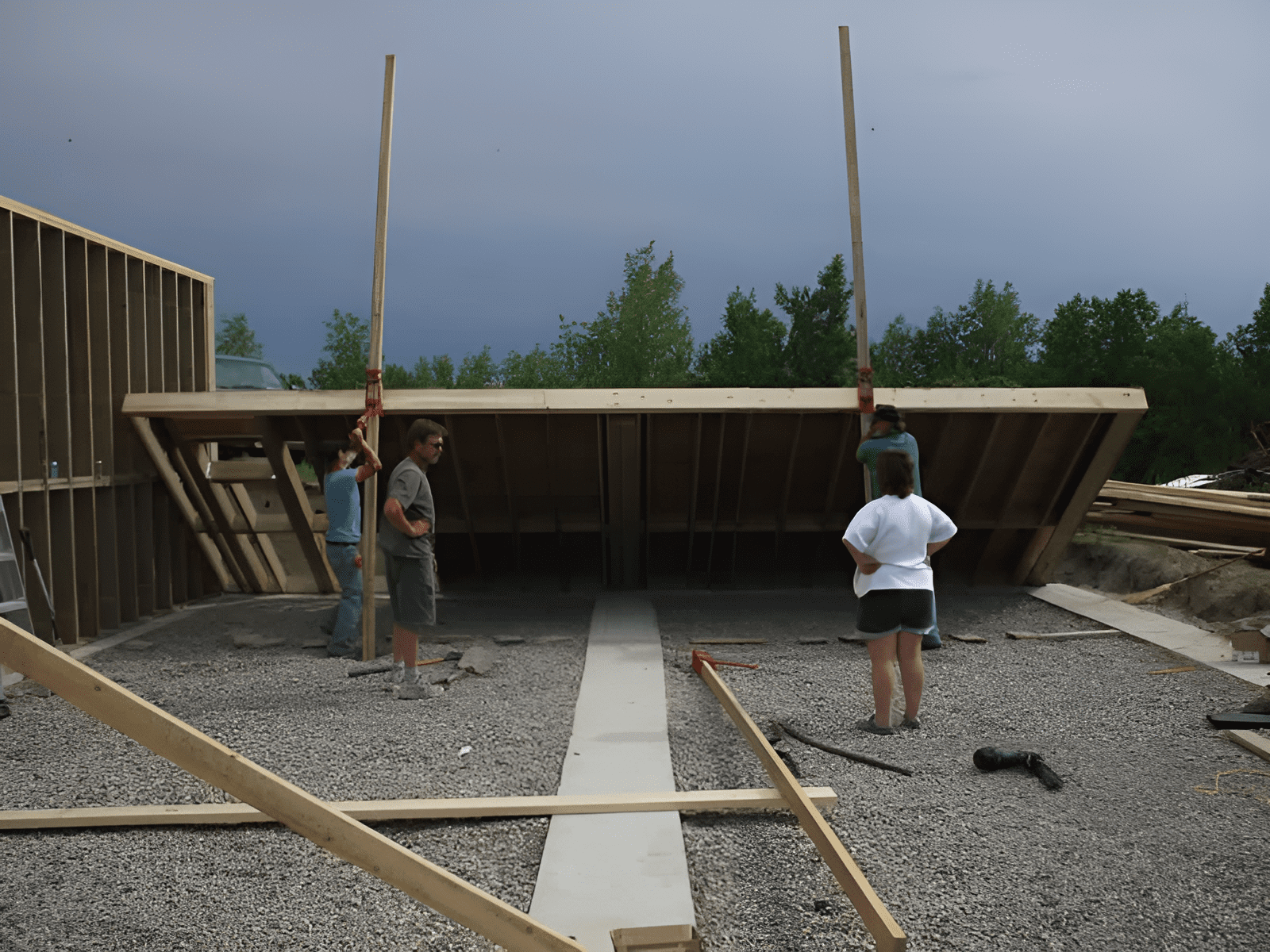

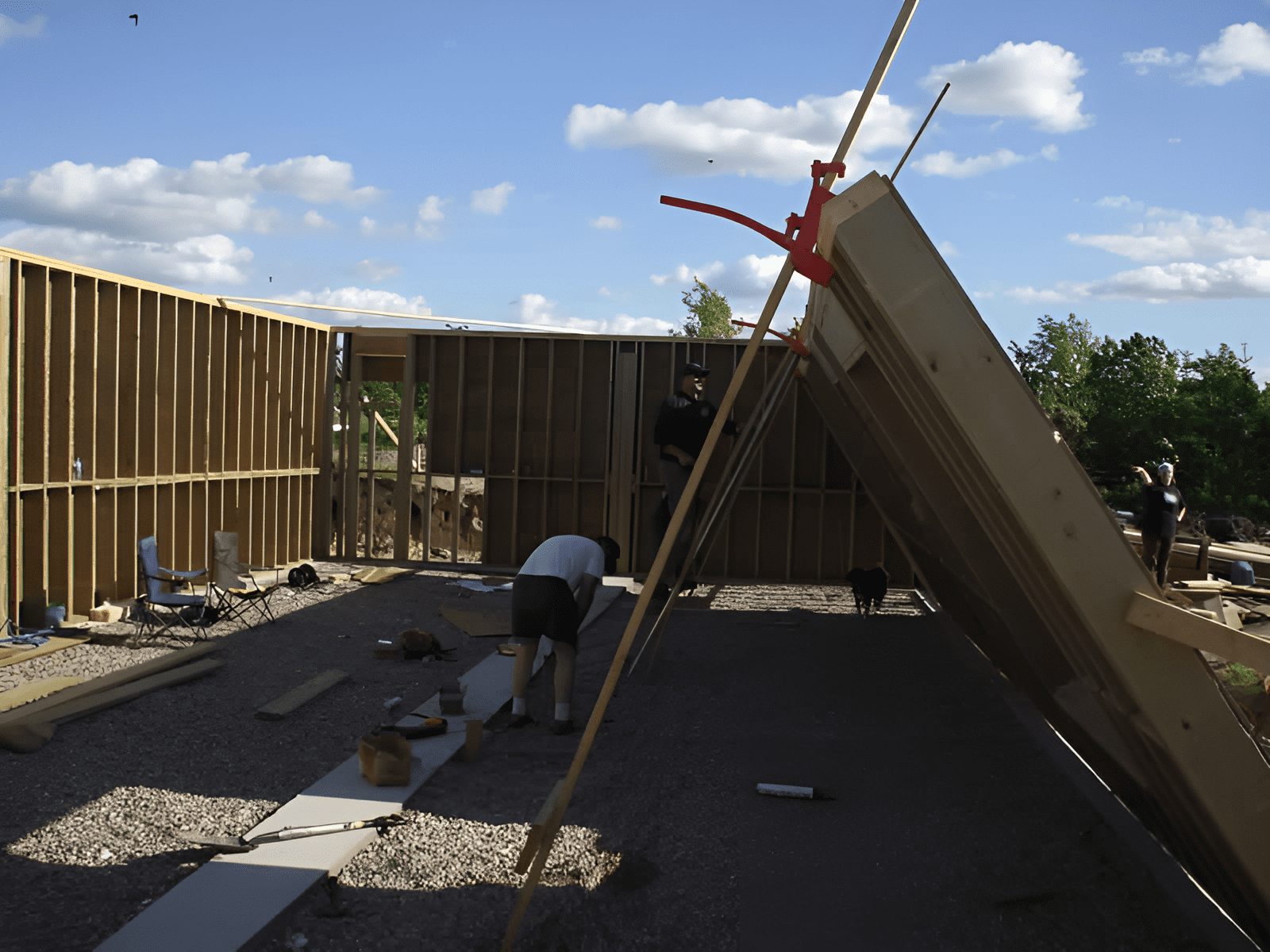

Prefab framing systems address Kentucky’s construction challenges by manufacturing structural essentials in controlled factories, then delivering components that assemble efficiently regardless of jobsite variables.

Custom wall panels, engineered floor systems, and roof trusses arrive precision-manufactured to your plan specifications. Components get built indoors where Kentucky weather can’t interfere, then shipped ready for rapid assembly.

Your crew isn’t battling weather, material inconsistencies, or dimensional variations during framing. They’re assembling factory-manufactured components built to exact specifications.

Components Built for Kentucky Construction

Factory-Manufactured Wall Panels

Panels arrive ready for immediate installation across Kentucky’s varied locations. Standard and custom heights from 8′ to 12’+ accommodate Kentucky’s architectural diversity from traditional to contemporary styles. Panel lengths from 8′-16′ depending on your design. 2×4 or 2×6 framing with spacing meeting Kentucky building codes. Advanced sheathing options including ZIP system for moisture management. Window and door openings precision-framed per your plans.

I-joist and open web truss options manufactured to plan specifications. L/360 minimum performance with upgrades for demanding applications. Spacing from 16″ to 24″ on center based on load requirements. Pre-framed openings for stairs, utilities, and access. Joist hangers and hardware included.

Custom trusses manufactured to your specifications. Sealed truss drawings included for permitting. Manufactured meeting Kentucky’s regional requirements per local codes.

Traditional framing in Kentucky takes 4-8 weeks depending on weather and crew availability. Prefab framing systems compress structural work to 1-3 weeks regardless of conditions—critical when Kentucky homes sell in 20 days and inventory remains tight at 4 months supply.

Kentucky Reality: A 3,200 sq ft home in Jefferson County completed its structural shell in 2 weeks—traditional framing would have required 6+ weeks. The builder moved to interior work five weeks ahead of schedule, capturing buyer demand in a market where 17.9% of homes sell above list price.

With Kentucky construction facing persistent labor challenges despite lower costs than national averages, finding experienced framers grows increasingly difficult. Prefab framing systems reduce skilled framing requirements by 60% while maintaining quality.

Owner-Builder Advantage: Kentucky’s affordable building costs attract many first-time owner-builders. Prefab framing transforms complicated structural work into achievable assembly with detailed instructions and precision components.

Factory-controlled manufacturing eliminates variables compromising Kentucky construction. No material degradation from weather exposure. No dimensional changes from humidity or temperature swings. No quality inconsistencies from rotating crews.

Finish Trade Efficiency: Consistent dimensional tolerances mean drywall, flooring, and trim contractors work efficiently without constantly adapting to framing irregularities—essential for the quality finishes Kentucky buyers expect.

Kentucky construction costs remain 4% below national averages at $90-$145 per square foot, but demand is closing gaps. Prefab framing locks in material costs during manufacturing, protecting budgets from price fluctuations while reducing on-site waste.

Kentucky’s favorable construction costs continue to attract first-time owner-builders. Prefabricated framing systems make complex builds more manageable by providing:

Predictable pricing that reduces financial uncertainty

Simplified on-site assembly that limits reliance on outside contractors

Factory-precision components that remove structural guesswork

Single-source coordination that streamlines ordering and logistics

For professional builders, prefabricated framing integrates easily with custom architectural designs while supporting healthier margins:

Precision-built wall panels compatible with virtually any design style

Faster framing timelines that allow interior trades to begin sooner

Consistent build quality that helps minimize callbacks

Clear documentation that supports smoother permitting with Kentucky building authorities

Prefab framing delivers strong advantages for multi-unit construction in Kentucky’s competitive development landscape:

Coordinated system deliveries that keep projects moving efficiently

Uniform quality across every unit

Reduced schedule risk, helping protect financing and timelines

Lower labor demands, improving overall project economics

Phase 1: Project Review

Submit architectural plans or select from standard models. Green-R-Panel’s team reviews your requirements and provides consultation with accurate pricing.

Phase 2: Design Development

Structural components are designed using AutoCAD software. Components manufactured to your specifications and Kentucky building codes. You review and approve layouts before manufacturing.

Phase 3: Controlled Manufacturing

Wall panels and engineered systems built in climate-controlled facilities. Quality control ensures components meet exact specifications.

Phase 4: Coordinated Delivery

Components organized for efficient delivery considering your timeline. Delivery coordinated with site readiness. Complete installation documentation provided.

Phase 5: Ongoing Support

Sealed truss drawings included with every project. Comprehensive customer support available throughout your construction process.

Builders across Kentucky consistently report measurable benefits when using prefabricated framing systems:

Labor Savings: Cutting skilled framing labor by up to 60% typically results in savings of $14,000–$26,000 on a 2,500 sq ft home

Material Efficiency: Factory-controlled production reduces material waste by approximately 15–20%, translating to $4,000–$9,000 in material savings

Faster Build Timelines: Shortening schedules by 4–6 weeks reduces carrying costs and speeds project completion—an important advantage in Kentucky’s active housing market

Improved Quality Outcomes: Fewer callbacks and warranty issues contribute to stronger long-term margins

Prefabricated framing systems are well suited to Kentucky’s construction environment and deliver reliable, efficient results across a wide range of projects.

Custom homes ranging from approximately 1,500 to 6,000+ square feet

Projects leveraging Kentucky’s resilient housing market

Owner-builder builds that benefit from simplified construction methods

Multi-unit developments where consistency and repeatability are critical

Replacement homes that require faster construction timelines

Complete construction drawings or a selected floor plan

Site details and foundation specifications

Target construction schedule

Local permitting and applicable code requirements

Plan review and preliminary pricing: 1–2 weeks

Design development and approvals: 2–4 weeks

Manufacturing and coordinated delivery: 6–8 weeks

Kentucky’s housing market rewards builders who adapt to demand while managing costs. With statewide prices rising 9.2% in January 2025 and homes selling in 20 days, opportunities abound for efficient builders who can deliver quality quickly.

Traditional methods face increasing challenges from labor costs and timeline pressures. Builders who master efficient construction methods while leveraging Kentucky’s 4% cost advantage below national averages will dominate the market.

Whether you’re planning a Louisville custom home, Lexington development, or Bowling Green project, prefab framing systems provide proven solutions for Kentucky’s resilient building market.

Kentucky prefab homes don’t require compromising quality or sacrificing Kentucky’s affordability advantage. With prefab framing systems, you get factory precision manufactured to your specifications while maintaining complete design freedom and the cost control that preserves Kentucky’s competitive positioning.

Contact Green-R-Panel today to discuss your Kentucky project. From initial consultation through delivery, we provide the expertise and support needed for successful construction in Kentucky’s resilient market.

Get started with a Kentucky-specific project consultation and discover how prefab framing systems capitalize on the Bluegrass State’s building opportunity.