Last Updated: November 2025

Alabama’s housing market tells a complicated story. Home sales dropped 18% in 2024 compared to 2023, hitting the lowest transaction numbers in recent years. Yet prices climbed 4.5% year-over-year to a median of $293,600 in September 2025, with homes selling in just 65 days.

The disconnect creates opportunities for builders who can deliver quality homes efficiently. Construction costs in Alabama range from $90 to $500 per square foot, with most projects averaging $350,000 to $750,000 before land purchase. The state ranks among America’s most affordable building markets, with costs 4% below the national average.

Alabama remains the sixth most popular destination for inbound migration in 2024, with residents from Georgia, Florida, Mississippi, Tennessee, and Texas relocating for Alabama’s 87.9 cost of living index—third-lowest in the country. The state gained 40,000 new residents in 2024 driven largely by domestic migration.

Yet builders face mounting challenges. The 2024 market saw 62,539 home sales—down 13,719 from 2023’s 76,258. Roughly half of Alabama homeowners enjoy mortgage rates below 4%, making them reluctant to sell. Active listings increased 34% to 16,786, but elevated mortgage rates above 6% continue suppressing buyer activity.

For custom builders and owner-builders across Alabama, from Huntsville to Mobile, the question becomes: how do you capitalize on in-migration and affordability advantages while navigating labor shortages and elevated interest rates?

The answer isn’t traditional prefab homes with their delivery complications and customization limits. Smart Alabama builders are adopting prefab framing systems—factory-manufactured structural components that arrive ready for efficient assembly while preserving complete design control.

Not all prefab approaches deliver the same results. Understanding the differences matters for Alabama builders.

Traditional prefab delivers finished modules on trucks. You select from manufacturer catalogs with limited modification options. Factory scheduling controls your timeline—typically 4-6 months from order to completion. Quality remains consistent but finish selections are restricted. You need crane access and precise foundation work. Customization gets limited to pre-approved changes. Critical decisions happen during factory production, giving you minimal local control.

This methodology works entirely differently. You receive precision-manufactured structural components—wall panels, floor systems, roof trusses—built to your specifications. Complete design flexibility means any architectural concept works. You control construction timing entirely. Precision structural elements arrive with unlimited finish material choices. Standard truck delivery works fine. Change finishes, layouts, and systems throughout construction. You maintain complete control over contractors and material sourcing.

The strategic advantage? Prefab framing delivers factory precision while you control design, finishes, timing, and contractors.

Alabama Delivery Challenges: Moving oversized modular homes through Alabama’s varied terrain—from urban Birmingham streets to rural county roads—creates serious logistical problems. Many desirable building sites can’t accommodate traditional prefab delivery requirements, especially in established neighborhoods or sites with mature trees.

Foundation Precision Across Regions: Alabama’s soil conditions vary dramatically from North to South. Achieving the exact foundations that modular homes require becomes challenging across different geological conditions. One measurement error means your home waits while corrections happen—expensive delays in Alabama’s competitive market.

Limited Regional Support: Most national prefab manufacturers don’t understand Alabama’s building requirements or regional specifications. Your local inspector knows Alabama—the prefab manufacturer’s team doesn’t.

Cost Reality Beyond Base Price: Advertised base pricing excludes Alabama site preparation, utility connections, delivery coordination, crane services, or customization fees. Final costs frequently exceed quality custom construction alternatives.

Prefab framing systems address Alabama’s construction challenges by manufacturing structural essentials in controlled factories, then delivering components that assemble efficiently regardless of jobsite variables.

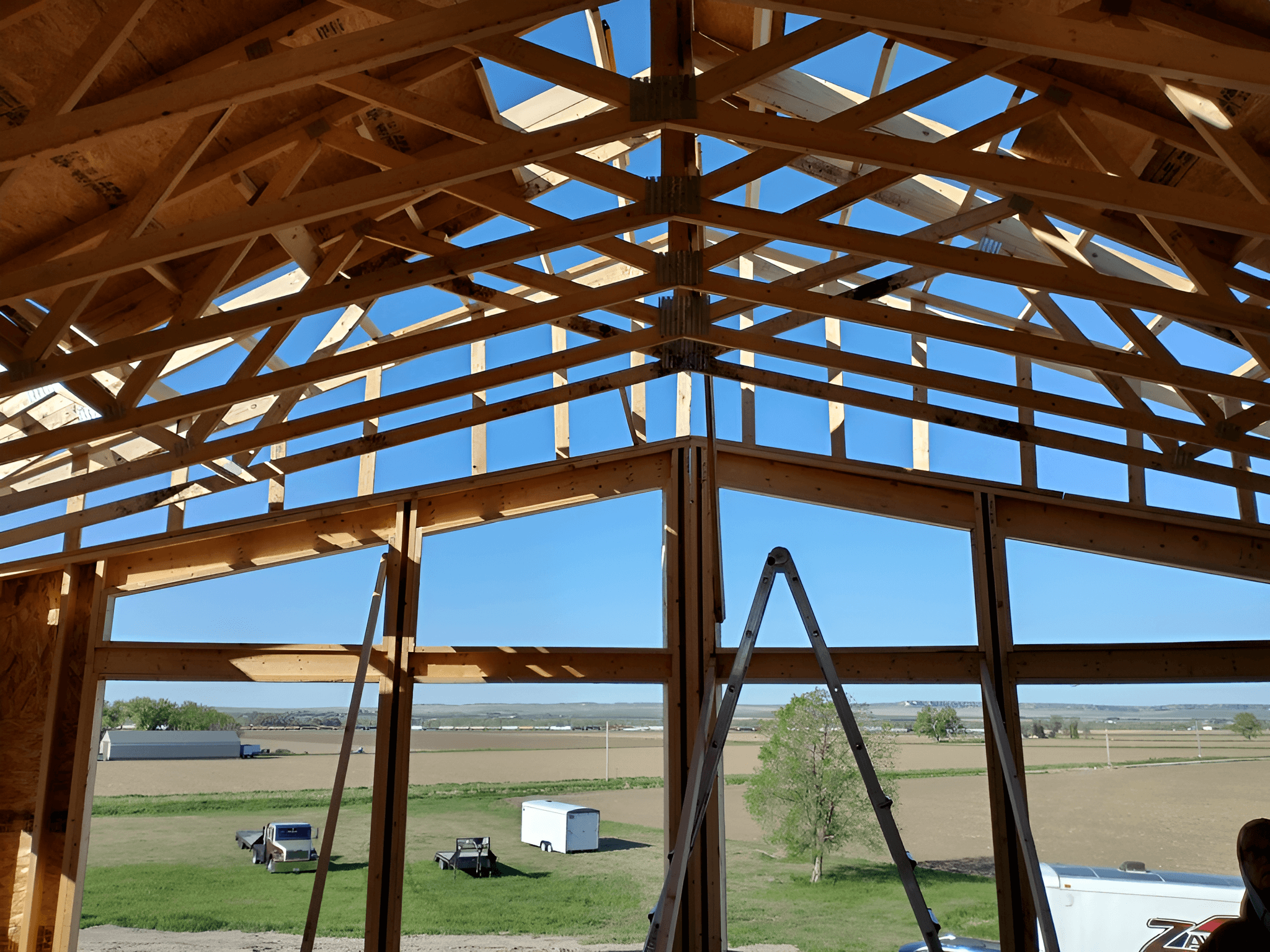

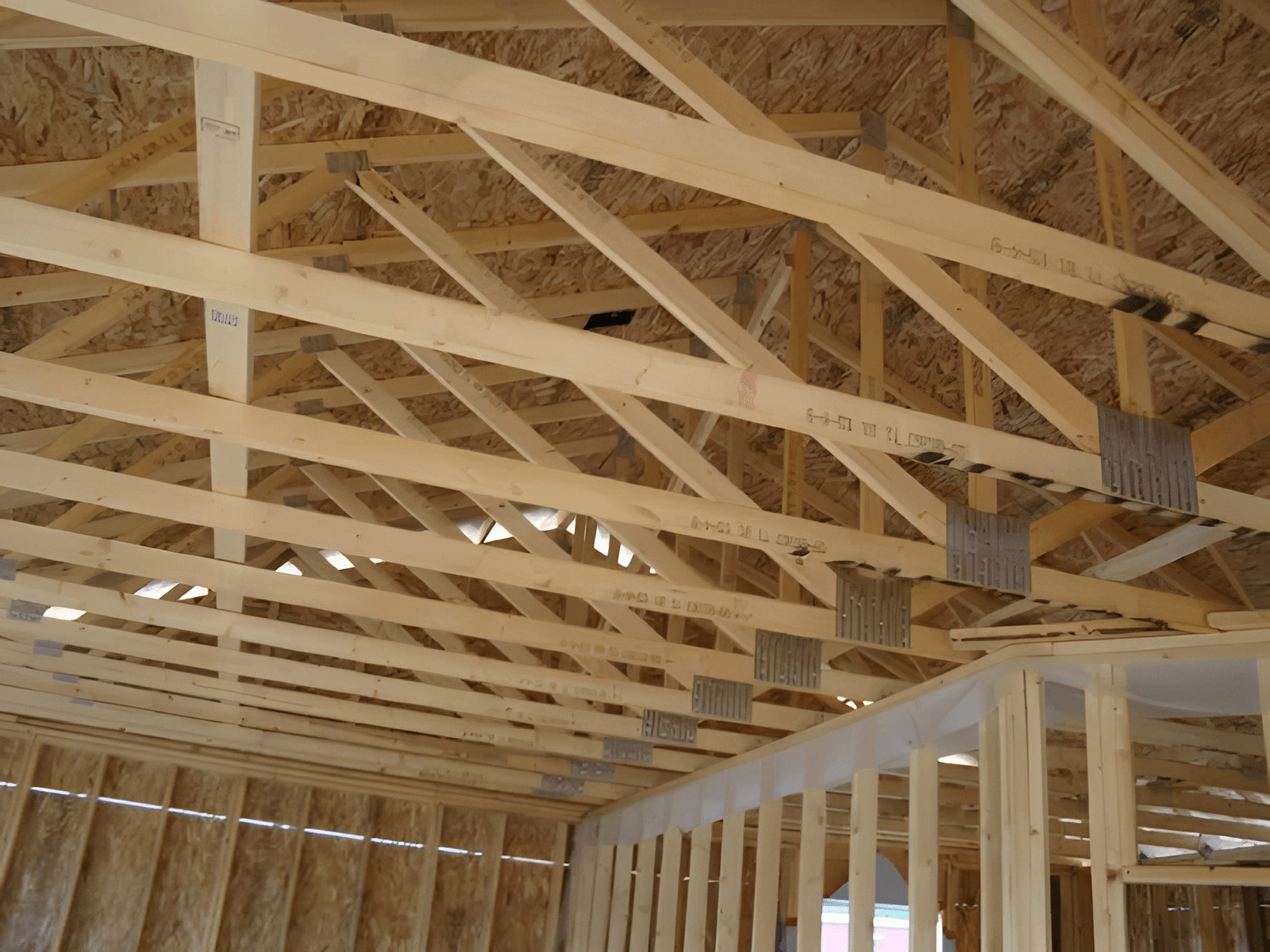

Custom wall panels, engineered floor systems, and roof trusses arrive precision-manufactured to your plan specifications. Components get built indoors where Alabama weather can’t interfere, then shipped ready for rapid assembly.

Your crew isn’t battling weather, material inconsistencies, or dimensional variations during framing. They’re assembling factory-manufactured components built to exact specifications.

Get your free copy of The DIY Owner-Builder’s Step-by-Step Guide to Shell Completion — a simple, practical roadmap to help you plan, frame, and complete your home’s shell with confidence.

Enter your email to download and receive helpful tips, updates, and exclusive insights to keep your project on track.

Traditional framing in Alabama takes 5-9 weeks depending on weather and crew availability. Prefab framing systems compress structural work to 1-3 weeks regardless of conditions.

Alabama Reality: A 3,400 sq ft custom home in Madison County completed its structural shell in 2 weeks—traditional framing would have required 6+ weeks. The builder moved to interior trades 5 weeks ahead of schedule.

With Alabama’s construction market facing labor challenges, finding experienced framers grows increasingly difficult. Prefab framing systems reduce skilled framing requirements by 60% while maintaining quality.

Owner-Builder Advantage: Alabama’s growing owner-builder community finds prefab framing transforms complicated structural work into achievable assembly with detailed instructions and precision components.

Factory-controlled manufacturing eliminates variables compromising Alabama construction. No material degradation from unexpected weather. No dimensional changes from humidity. No quality inconsistencies from rotating crews.

Finish Trade Efficiency: Consistent dimensional tolerances mean drywall, flooring, and trim contractors work efficiently without constantly adapting to framing irregularities.

Alabama construction faces material cost volatility during peak seasons. Prefab framing locks in material costs during manufacturing, protecting budgets from price fluctuations and reducing on-site waste.

Factory-Manufactured Wall Panels

Panels arrive ready for immediate installation. Standard and custom heights from 8′ to 12’+ accommodate Alabama’s architectural diversity from traditional Southern styles to modern contemporary. Panel lengths from 8′-16′ depending on your design. 2×4 or 2×6 framing with spacing meeting Alabama building codes. Advanced sheathing options including ZIP system for moisture management. Window and door openings precision-framed per your plans.

I-joist and open web truss options manufactured to plan specifications. L/360 minimum performance with upgrades for demanding applications. Spacing from 16″ to 24″ on center based on load requirements. Pre-framed openings for stairs, utilities, and access. Joist hangers and hardware included.

Custom trusses manufactured to your specifications. Sealed truss drawings included for permitting. Manufactured meeting Alabama’s regional requirements per local codes.

Alabama’s affordability attracts many first-time owner-builders. Prefab framing systems transform challenging construction into achievable projects:

Professional builders find prefab framing integrates seamlessly with unique designs while improving margins:

Multi-unit projects benefit from prefab framing advantages:

Phase 1: Project Review

Submit architectural plans or select from standard models. Green-R-Panel’s team reviews your requirements and provides consultation with accurate pricing.

Phase 2: Design Development

Structural components are designed using AutoCAD software. Components manufactured to your specifications and Alabama building codes. You review and approve layouts before manufacturing.

Phase 3: Controlled Manufacturing

Wall panels and engineered systems built in climate-controlled facilities. Quality control ensures components meet exact specifications.

Phase 4: Coordinated Delivery

Components organized for efficient delivery considering your timeline. Delivery coordinated with site readiness. Complete installation documentation provided.

Phase 5: Ongoing Support

Comprehensive customer support available throughout your construction process. Sealed truss drawings included with every project.

Alabama builders consistently report significant advantages with prefab framing systems:

Labor Cost Reduction: 60% reduction in skilled framing labor typically saves $14,000-$24,000 on a 2,500 sq ft home

Material Efficiency: Controlled manufacturing reduces waste by 15-20%, saving $4,000-$8,000 in materials

Timeline Acceleration: 3-7 week timeline reduction saves carrying costs and accelerates completion

Quality Improvements: Reduced callbacks and warranty claims improve long-term profitability

Prefab framing systems deliver optimal results for specific Alabama construction needs:

Ideal Applications:

Essential Information:

Realistic Timeline:

Trusted by do-it-yourself owner-builders and professionals for 17+ years—build smarter with Green-R-Panel’s proven support.

Alabama’s housing market rewards builders who adapt to demand while managing costs. With statewide prices rising 5.6% year-over-year in January 2025 and 14% of homes selling above listing price, opportunities exist for efficient builders.

Traditional methods face increasing challenges from labor costs and material volatility. Builders who master efficient construction methods will lead the market while competitors struggle with persistent problems.

Whether you’re planning a Huntsville tech-sector home, Birmingham urban project, or coastal Mobile construction, prefab framing systems provide proven solutions for Alabama’s affordable building market.

Alabama prefab homes don’t require compromising your vision or accepting delays. With prefab framing systems, you get factory precision manufactured to your specifications while maintaining complete design freedom and cost control.

Contact Green-R-Panel today to discuss your Alabama project. From initial consultation through delivery, we provide the expertise and support needed for successful construction in Alabama’s competitive market.

Get started with an Alabama-specific project consultation and discover how prefab framing systems optimize your building project.