Last updated: September 2025

Pennsylvania’s construction market tells a story of opportunity mixed with serious obstacles. The average home value in Pennsylvania is $286,351, up 2.9% over the past year, while there were 42,272 homes on the market in July 2025, up 9.5% over the same time last year. Despite increased inventory, Pennsylvania builders face a crushing reality: PA faces a skilled trades shortfall of 300,000 workers by 2030.

For DIY owner-builders and custom builders across Pennsylvania, this creates a perfect storm. Do you battle increasing costs, unreliable subcontractors, and project delays—or find a smarter path forward?

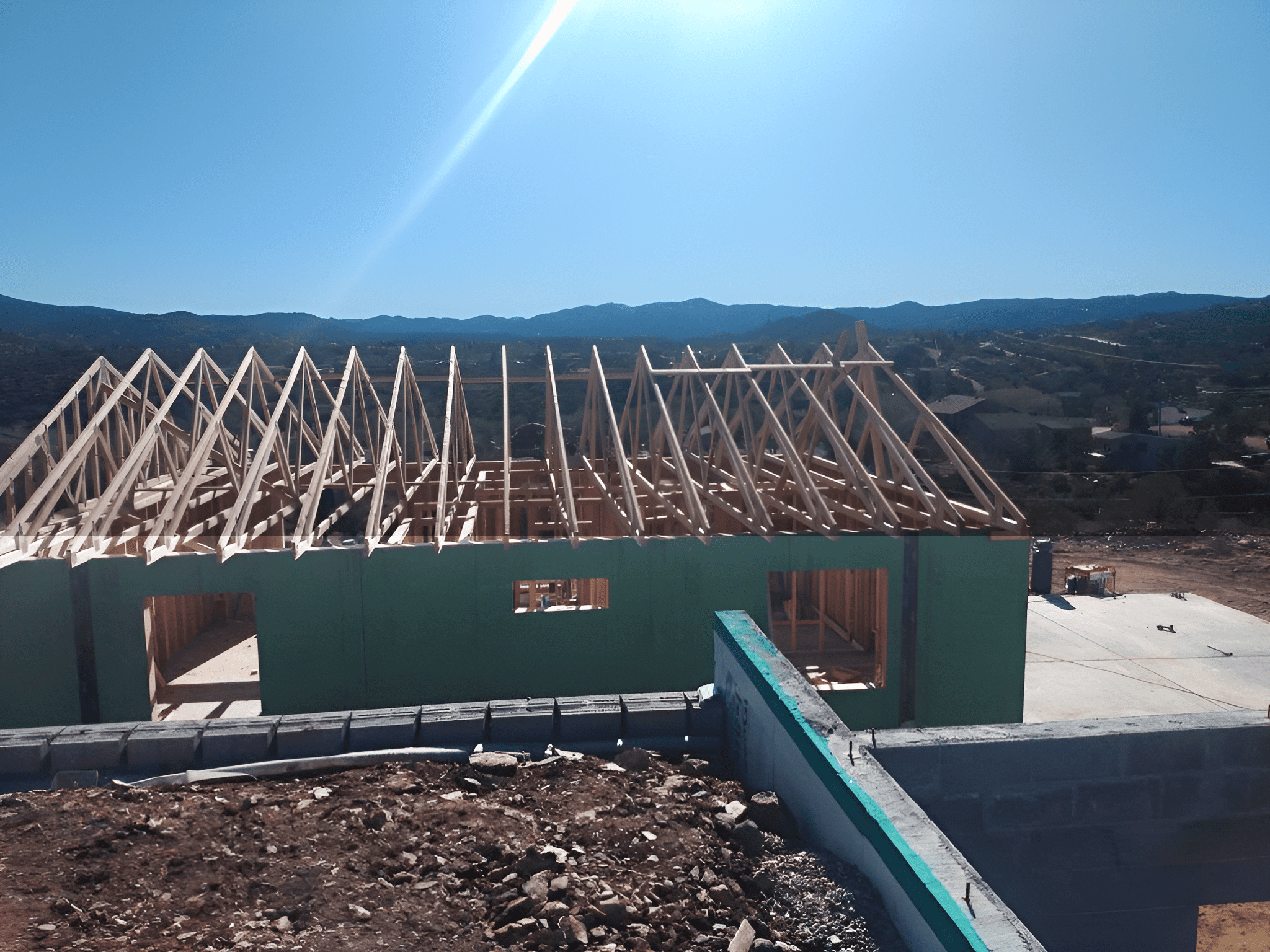

The answer isn’t traditional “prefab homes” delivered on trucks. It’s prefab framing systems—factory-manufactured wall panels, engineered floor systems, and roof trusses that arrive organized and ready for rapid assembly. You maintain complete design control while eliminating the biggest construction bottlenecks.

Green-R-Panel delivers this hybrid approach: precision-manufactured structural components that speed up your build without forcing you into cookie-cutter designs. It’s the construction evolution Pennsylvania builders need to stay competitive in today’s challenging market.

Forget everything you think you know about “prefab homes.” Prefab framing systems aren’t complete houses—they’re intelligent building components that solve your biggest construction challenges.

Full Prefab/Modular Homes:

Prefab Framing Systems:

Key advantage: Prefab framing systems deliver manufacturing precision and speed benefits while preserving complete control over design, finishes, timeline, and local contractor relationships.

The result? You’re not buying a prefab house—you’re buying a proven method to build the custom home you actually want, faster and with fewer headaches.

Pennsylvania builders aren’t just dealing with market fluctuations—they’re navigating a full-scale industry crisis that makes traditional construction increasingly risky.

These aren’t just statistics—they’re the daily reality driving Pennsylvania’s smartest builders toward prefab framing solutions.

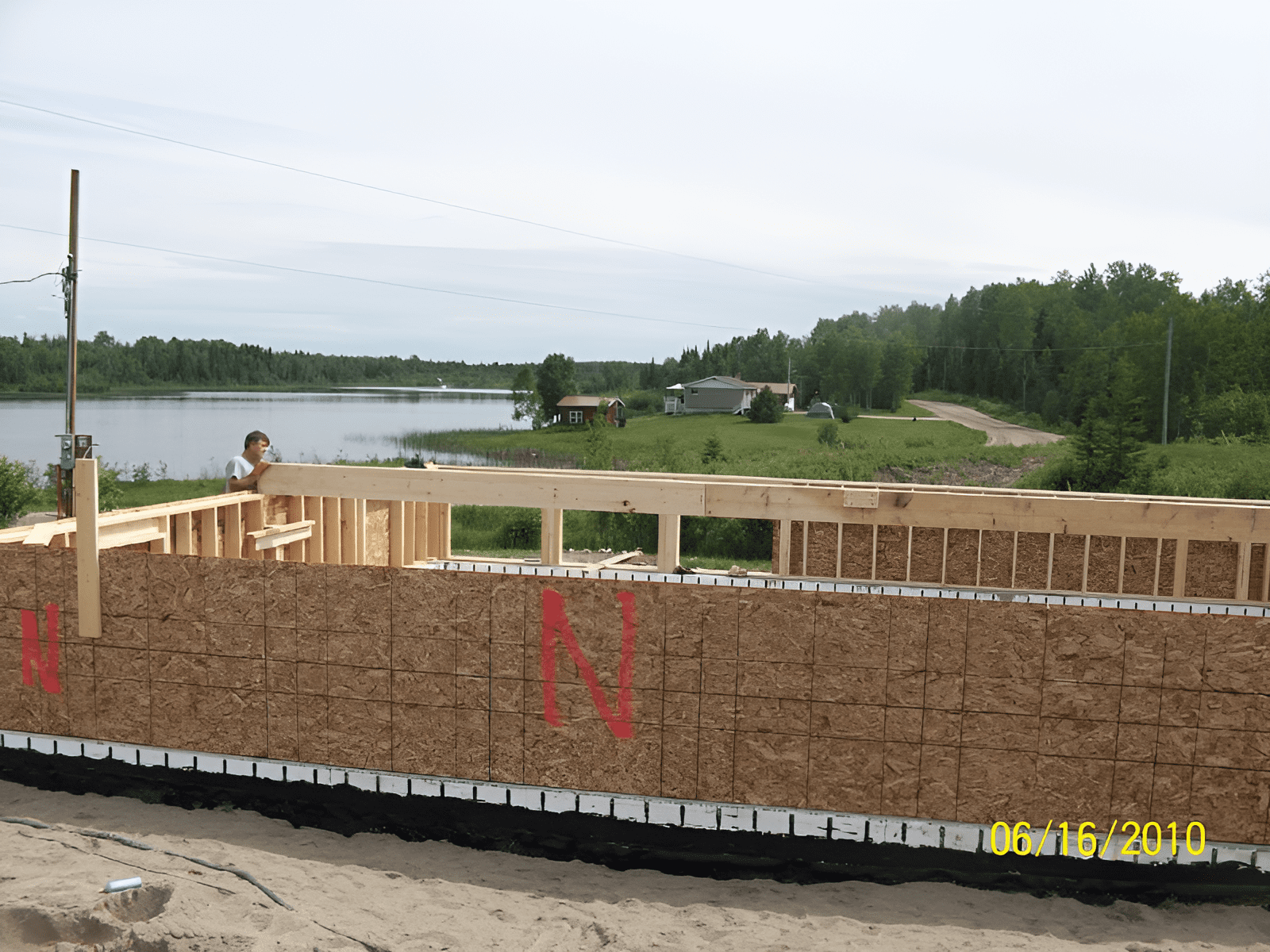

Traditional stick-framing for a 2,800 sq ft home in Pennsylvania averages 4-5 weeks. Prefab framing systems cut this to 1.5-2 weeks for shell completion.

Real speed advantages:

With Pennsylvania’s skilled labor crisis, prefab framing systems reduce your dependence on hard-to-find experienced framers by up to 60%.

How it works:

Controlled factory environments deliver consistency impossible with traditional field construction.

Quality advantages:

While material costs may be slightly higher upfront, total project economics typically improve through:

Get your free copy of The DIY Owner-Builder’s Step-by-Step Guide to Shell Completion — a simple, practical roadmap to help you plan, frame, and complete your home’s shell with confidence.

Enter your email to download and receive helpful tips, updates, and exclusive insights to keep your project on track.

Why they choose prefab framing:

Real project benefits:

Strategic benefits:

Development advantages for 5-10 unit projects:

Precision-Manufactured Wall Panels

Standard specifications:

Two proven options:

Professional engineering included:

Optional Upgrades Available

Pennsylvania’s evolving building codes create complexity, especially for:

Factory-manufactured components with engineering support help ensure your project meets Pennsylvania’s building standards without guesswork.

With Pennsylvania’s construction workforce challenges—nearly 40% of skilled workers expected to exit by 2031—prefab framing systems offer sustainable solutions:

Pennsylvania’s geographic position creates unique logistical advantages for prefab framing:

Custom Home in Bucks County

Project: 3,400 sq ft contemporary home with complex architectural features

Results:

Townhome Development in Lancaster County

Project: 6-unit townhome development

Results:

Owner-Builder Project in Chester County

Project: 3,100 sq ft family home with walkout basement

Results:

Step 1: Project Consultation and Plan Review

Step 2: Custom AutoCAD Engineering

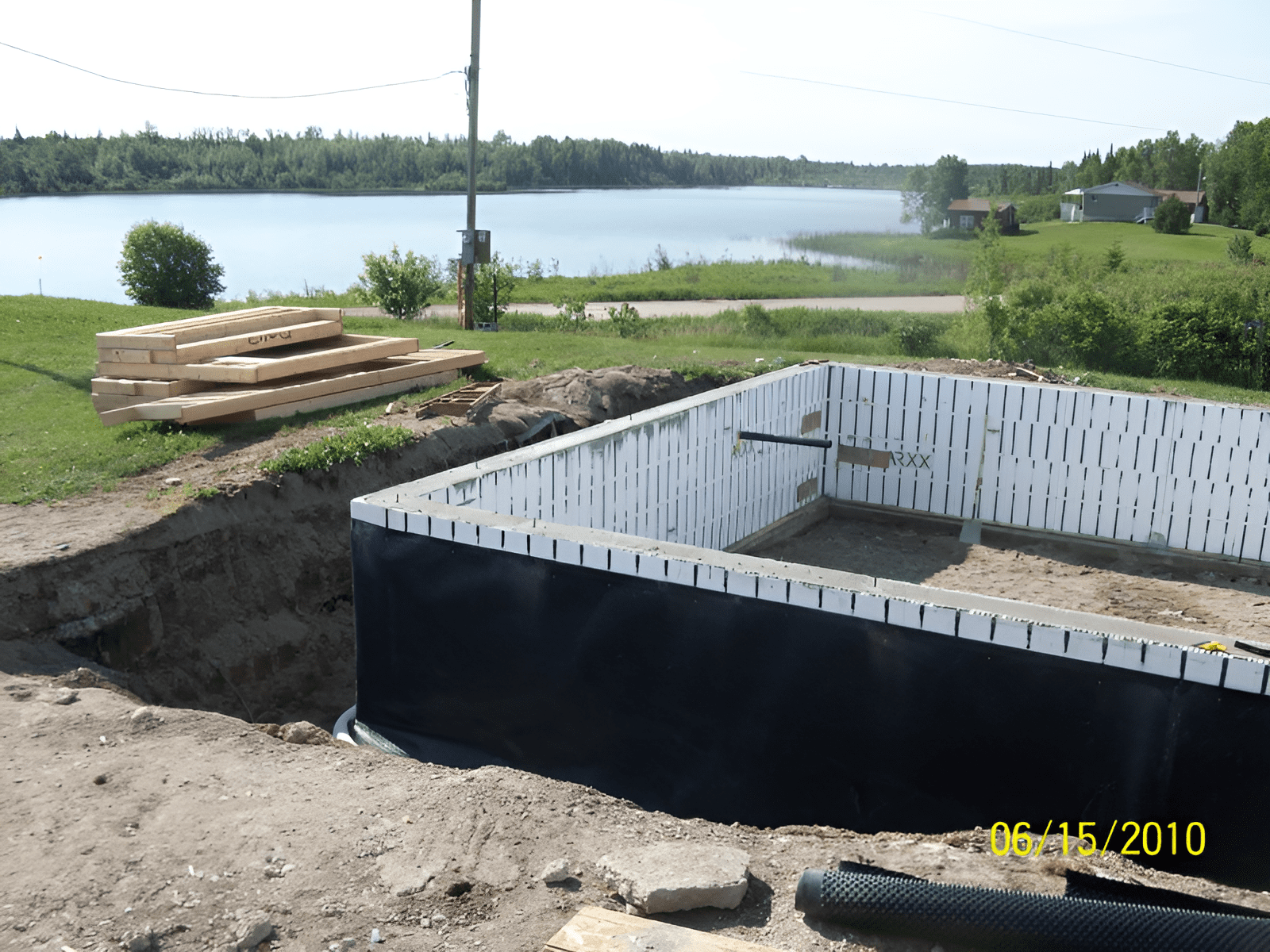

Step 3: Controlled Factory Manufacturing

Step 4: Coordinated Delivery and Installation Support

Ideal applications:

Consider alternatives if:

Trusted by do-it-yourself owner-builders and professionals for 20+ years—build smarter with Green-R-Panel’s proven support.

Pennsylvania’s construction landscape is changing rapidly. The skilled trades shortfall of 300,000 workers by 2030 isn’t a future problem—it’s today’s reality affecting every builder in the Commonwealth.

Smart Pennsylvania builders are already using prefab framing systems to gain decisive advantages:

The question isn’t whether prefab framing systems work—it’s whether you can afford to keep using traditional methods while your competition leverages every advantage modern manufacturing offers.