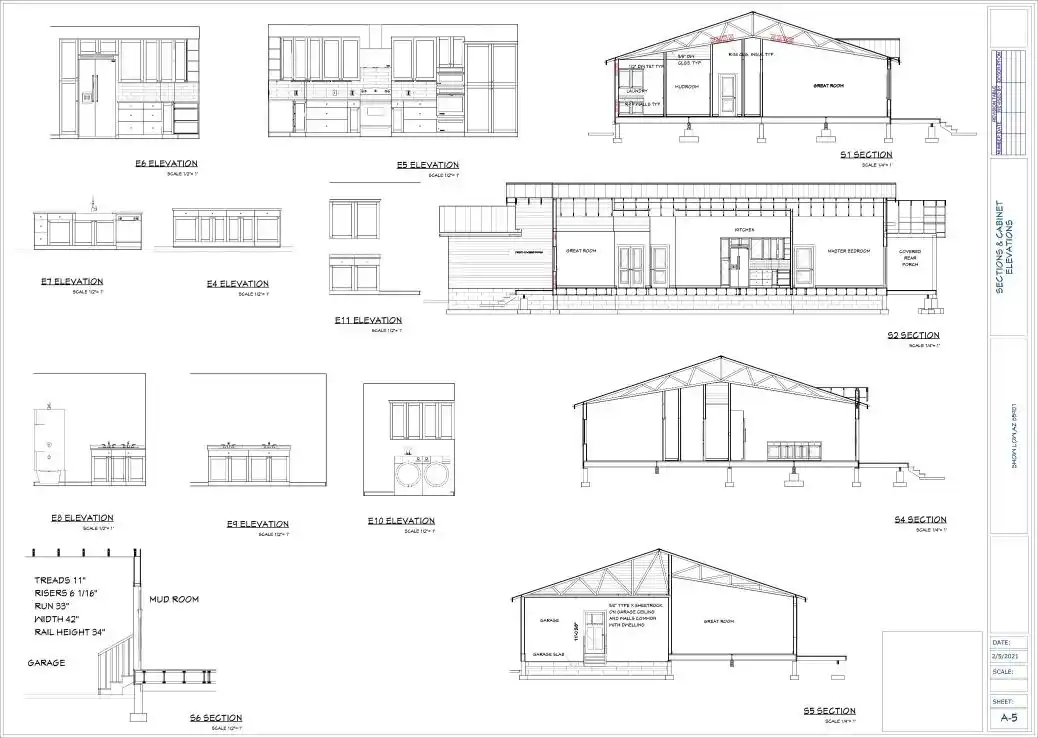

Each component sub-system supplied as part of a Green-R-Panel prefabricated panelized home kit comes with two detailed structural drawings. Using advanced AutoCAD software, our technical team converts your architectural and structural plans into accurate, code-compliant, and production-ready designs for every wall, floor, and roof component.

Before manufacturing begins, builders are required to review and approve all drawings. This process ensures accuracy, minimizes onsite adjustments, and helps deliver a fast, simple, and stress-free construction experience.

Each System Layout acts as a numbered installation map that guides your entire framing process. It shows exactly where every wall panel, roof truss, floor system I-joist, open-web truss, and LVL support beam should be placed within the structural envelope of your building. These layouts provide a clear visual overview, helping builders assemble each component quickly and correctly.

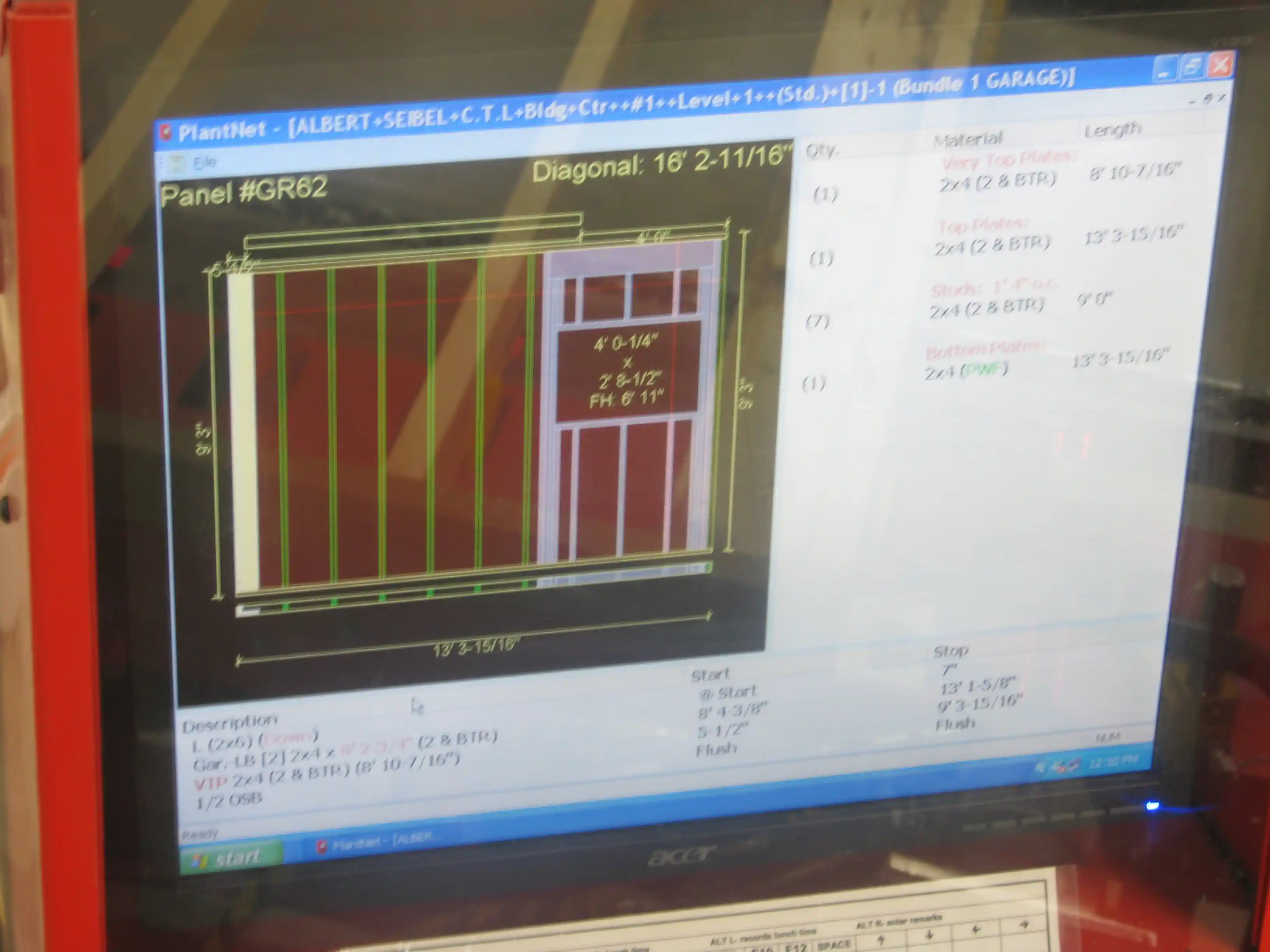

Each numbered component shown in the System Layout includes a corresponding Shop Elevation drawing. These detailed drawings specify all essential manufacturing information—such as overall dimensions, window and door openings, stud spacing, and other key framing details.

Shop Elevations ensure every prefabricated part fits perfectly during installation, maintaining Green-R-Panel’s standards of precision, quality, and efficiency.

Get your free copy of The Do-It-Yourself Owner-Builder’s Step-by-Step Guide to Shell Completion — a simple, practical roadmap to help you plan, frame, and complete your home’s shell with confidence.

Enter your email to download and receive helpful tips, updates, and exclusive insights to keep your project on track.

Our factory designers are highly trained technical professionals who use a dedicated suite of design and production tools specifically created for automated manufacturing. Their work requires a unique combination of engineering knowledge, spatial reasoning, and software expertise—all focused on delivering precision-built framing components for every project.

1. Analyze Building Plans

Our designers carefully review each architectural and structural blueprint to understand the building’s design, dimensions, and requirements for wall panels, roof trusses, and floor systems.

2. Perform Engineering Calculations

They determine the correct size, spacing, and configuration of all structural members and connectors. These calculations account for expected loads—such as weight, wind, and snow—to ensure structural safety and full compliance with engineering standards.

3. Design Components with Advanced Software

Using specialized AutoCAD-based design software, designers create precise 2D and 3D models for each wall panel, truss, and floor component. These models define every connection, joint, and geometric detail needed for accurate automated production.

4. Optimize for Performance and Cost

Each design is refined to achieve maximum structural efficiency while reducing material waste and simplifying manufacturing and installation. This optimization process ensures every Green-R-Panel system delivers both quality and value.

5. Generate Detailed Documentation

Designers produce complete layout and elevation drawings for each project. These documents guide manufacturing, streamline assembly, and ensure smooth communication between design, production, and on-site teams.

6. Ensure Code Compliance

All designs are verified to meet or exceed local and national building codes. This ensures every component system—wall, floor, and roof—is safe, durable, and fully compliant.

For over 17 years, Green-R-Panel has helped builders and DIY clients bring projects to life with speed, accuracy, and full design support.

Get your free project consultation and quotation today — let’s build your success.

Our factory truss and wall panel designers employ sophisticated software developed for automated structural building component production. Specialized programs by Mitek and Alpine go beyond generic CAD software by incorporating engineering analysis capabilities, material databases, and features tailored to the unique requirements of component design and manufacturing:

From custom homes to multi-family developments, your plans are converted into an integrated building envelope package designed for speed and accuracy. To streamline installation, each prefabricated framing system component is delivered with number labels to match the layout drawings. The framing crew simply follows the plan from foundation to roofline. It’s that easy!

Green-R-Panel’s drawing package is your crew’s roadmap to faster, easier construction. Whether you’re building your first home or your fiftieth, our layout and shop drawings eliminate delays, confusion, and waste.

Have plans ready? Let us turn them into a prefabricated framing system—designed to go up fast and built to last.

Reach out by phone, email, or our contact form to discuss your project’s design, schedule, and specific needs. We’ll answer your questions and explain how Green-R-Panel can streamline your build.

Request a no-obligation cost for your prefab framing package. Already have plans? Send them in by upload or email. Need plans? We offer drafting services, 21 standard home models, or can work from your sketch.

Get a quote covering the building envelope components. Review the proposal, ask questions, make any needed changes, and confirm your order with a 10% deposit to begin production.

Our team prepares detailed AutoCAD layouts and drawings for the structural shell components package which you review and must approve before we start manufacturing.

We coordinate delivery from our nationwide factory network, shipping flat-packed, clearly labelled bundles organized for build order. Around-the-clock support is available throughout your project.

Green-R-Panel provides a comprehensive, ready-to-assemble home framing system that includes:

Green-R-Panel Panelized home kit systems are trusted by Do-It-Yourself owner-builders across the U.S. From single homes to multi-unit developments, we help you frame faster, save money, and get your structure up, under roof and weather tight in a fraction of the time.