Last updated: September 2025

California’s housing market presents a paradox of opportunity and impossibility. The California Association of Realtors predicts a 10.5% increase in home sales in 2025, with around 304,000 single-family homes expected to change hands, while the state’s median price is climbing 4.6 percent to reach $909,400 in 2025. Yet payments for a mid-tier home were over $5,900 a month in June 2025—a 82 percent increase since January 2020, creating an affordability crisis where only about 16% of California households will be in a position to afford a median-priced home.

For self-builders and custom builders navigating California’s complex market, traditional construction methods compound these affordability challenges. Rising labor costs, regulatory complexity, and extended timelines push projects beyond reach for many families who simply want to build their dream home.

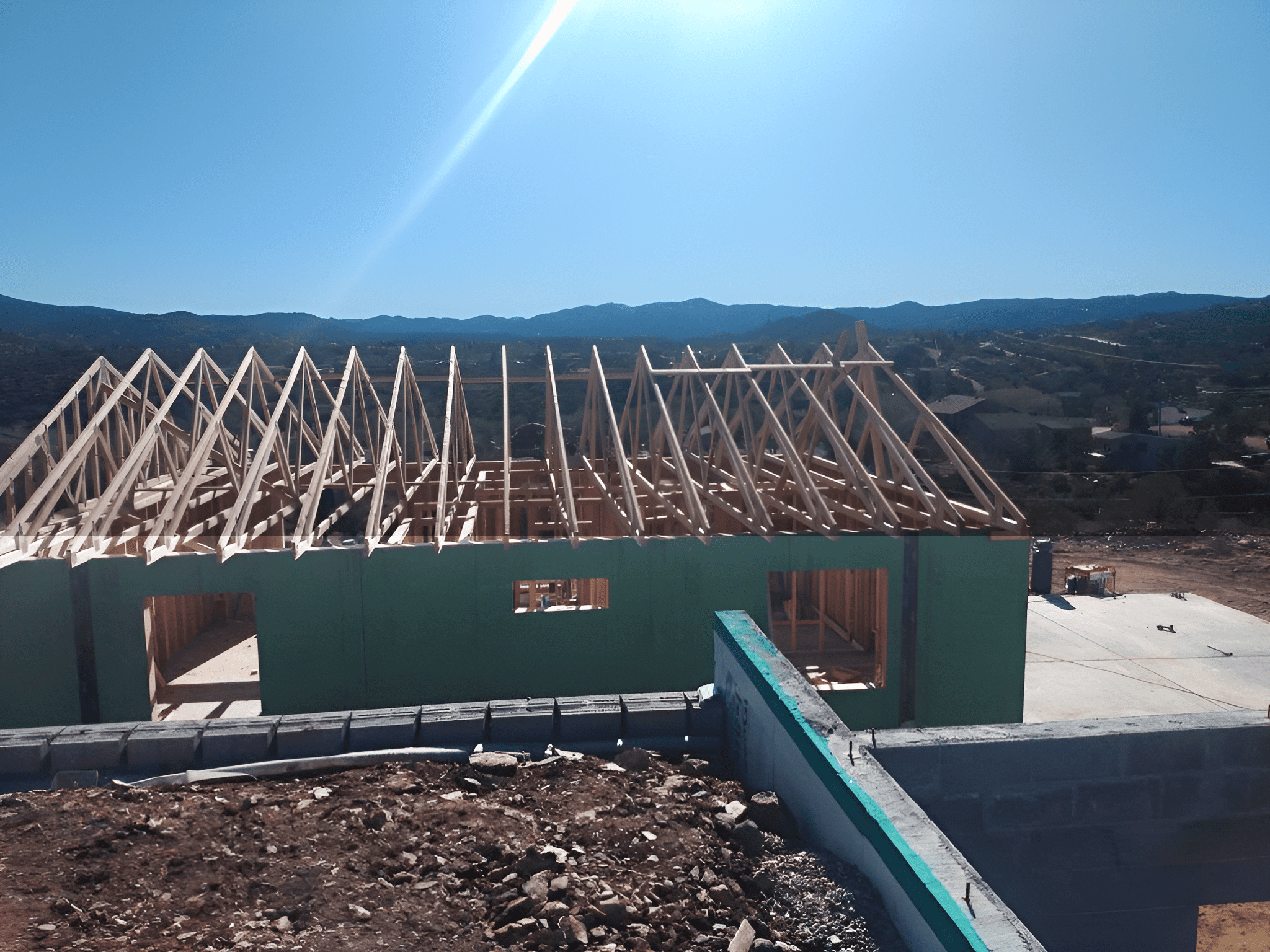

The solution isn’t waiting for market corrections or accepting cookie-cutter “prefab homes”—it’s prefab framing systems. Factory-manufactured wall panels, engineered floor systems, and roof trusses that arrive at your California jobsite organized for efficient assembly. You maintain architectural control while dramatically reducing the construction costs and timelines that make California building so challenging.

Green-R-Panel delivers this cost-control advantage: precision-manufactured structural components that compress construction schedules and reduce labor dependencies without sacrificing design freedom. It’s the intelligent approach California builders need to make custom construction financially viable again.

Traditional “prefab homes” often mean complete factory-built modules with limited customization options. For California’s diverse building requirements and design preferences, prefab framing systems offer a more flexible solution.

Complete Prefab/Modular Home Limitations:

Prefab framing systems deliver manufacturing efficiency and cost control while maintaining complete flexibility for California’s unique regulatory environment and design preferences.

Your California project receives:

You’re not buying a prefab house—you’re investing in a proven system to build the custom California home your family wants, faster and more affordably than traditional construction allows.

Get your free copy of The DIY Owner-Builder’s Step-by-Step Guide to Shell Completion — a simple, practical roadmap to help you plan, frame, and complete your home’s shell with confidence.

Enter your email to download and receive helpful tips, updates, and exclusive insights to keep your project on track.

California builders face unique combinations of challenges that make traditional construction increasingly expensive and risky.

Labor Market Realities

Regulatory Complexity Costs

Financial Impact on California Projects

These aren’t temporary market fluctuations—they’re structural challenges driving California’s smartest builders toward prefab framing solutions that control costs and timelines.

Construction Speed That Reduces Financing Costs

Traditional stick-framing for a 3,500 sq ft California home averages 6-8 weeks due to regulatory complexity. Prefab framing systems compress this to 2.5-3 weeks for shell completion.

Real cost-reduction benefits:

Labor Cost Control Strategy

In California’s expensive labor market, prefab framing systems reduce dependence on high-cost skilled framers by up to 70%.

Cost control advantages:

Manufacturing Quality That Meets California Standards

Factory-controlled production delivers consistent quality that meets California’s demanding building codes without field errors.

Quality assurance benefits:

Total Project Economics

While component costs may be slightly higher upfront, total project costs typically decrease through:

Cost-control benefits:

Practical affordability advantages:

Market positioning advantages:

Development economics for 3-8 unit California projects:

California-optimized specifications:

Two California-compliant options:

California code compliance included:

California Upgrade Options

Building Code Navigation

California’s building codes create unique complexity:

Factory-manufactured components with professional support help ensure your project meets California’s complex regulatory environment efficiently, reducing permit delays and compliance costs.

Prefab framing systems support California’s environmental goals through reduced waste, shorter construction timelines, and improved building performance.

California construction costs continue escalating beyond many families’ reach. Payments for a mid-tier home were over $5,900 a month in June 2025, while traditional construction methods add unnecessary time, waste, and labor costs to every project.

The critical question isn’t whether prefab framing systems work—it’s whether you can afford to keep using traditional methods that add unnecessary costs while your competition leverages manufacturing efficiency to deliver better homes more affordably.

Trusted by do-it-yourself owner-builders and professionals for 20+ years—build smarter with Green-R-Panel’s proven support.

California’s housing crisis demands innovative solutions. While others struggle with escalating costs and extended timelines, smart builders are using prefab framing systems to deliver superior homes at controlled costs with compressed schedules.

Whether you’re an owner-builder making your California dream home financially viable, a custom builder seeking cost-control advantages, or a small developer needing consistent quality with predictable economics, prefab framing systems provide a proven path to success in California’s challenging market.

Your next California project could demonstrate that quality custom construction can still be affordable when you build smarter, not just harder.