Last updated: October 2025

Oregon’s housing market is under pressure like never before. The state needs to build roughly 584,000 new homes over the next 20 years—with nearly 140,000 needed immediately just to meet today’s demand. Yet, instead of ramping up, new housing permits have dropped sharply, from 22,000 in 2019 to just 14,600 in 2024—a 34% decline. At the same time, median listing prices hover above $540,000 in many communities, making the dream of homeownership feel increasingly out of reach.

This combination of high demand, limited supply, and rising costs is pushing Oregonians to think outside the box—and explore innovative ways to build smarter, faster, and more affordably.

If you’re a hands-on Do-It-Yourself owner-builder in Oregon, you already know the hurdles:

It’s enough to make traditional construction feel like an uphill battle—especially if you’re trying to build a home that reflects your personal vision without breaking the bank.

Prefab homes have grown in popularity across Oregon for good reason. By building off-site, they reduce weather delays, speed up timelines, and help control costs.

But there’s a catch:

For many, that lack of flexibility takes away the satisfaction of building a truly custom home.

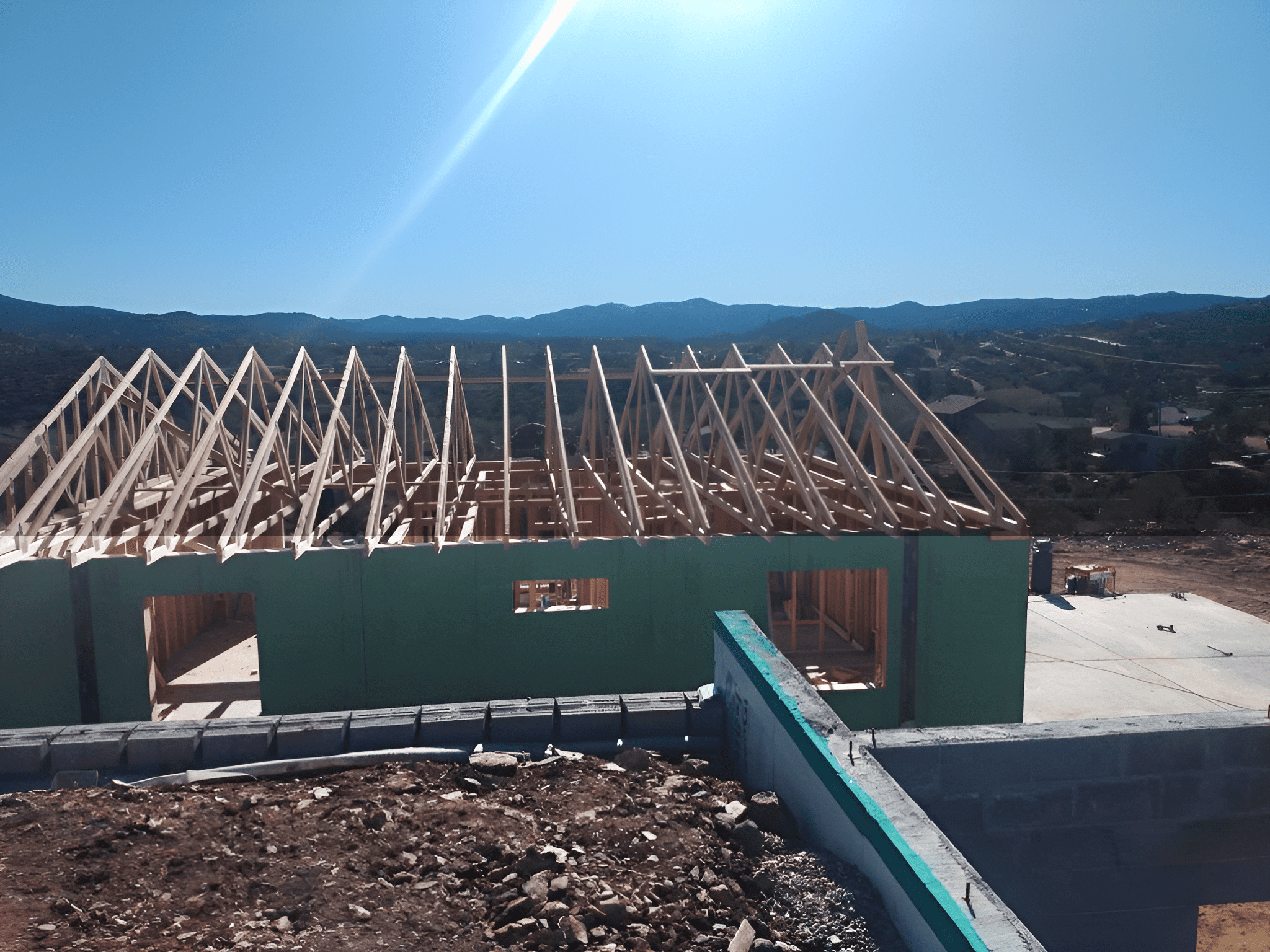

This is where prefab framing systems—like those offered by Green-R-Panel—change the game. Instead of delivering a pre-finished home, these systems provide a precision-engineered framing package: wall panels, roof trusses, and optional floor systems, delivered to your site ready for assembly.

The result?

Across Oregon—from Portland’s urban infill neighborhoods to coastal towns and the Cascade foothills—DIY owner-builders are discovering that prefab framing systems strike the perfect balance. They deliver the efficiency of prefab with the creative freedom of traditional construction.

If you’ve been researching Oregon prefab homes and feeling boxed in by high prices or limited designs, prefab framing systems open the door to a smarter, more flexible way to build. For many DIY builders, it’s the ideal middle ground—affordable, customizable, and perfectly suited to the challenges of the Pacific Northwest.

The Pacific Northwest Construction Crisis

Oregon builders face a unique combination of challenges that make prefab solutions not just attractive, but necessary for competitive survival:

Regulatory Complexity Oregon’s building codes are among the nation’s most stringent, with rapidly evolving energy efficiency requirements, seismic standards, and environmental protections that make traditional construction increasingly complex and time-consuming.

Extended Wet Season Impact Oregon’s 6-month rainy season creates construction challenges unknown in drier climates. Traditional framing exposes materials to moisture for extended periods, leading to quality issues, delays, and waste that can devastate project budgets.

Labor Market Disruption The state’s construction labor shortage hit 91% of contractors in 2024, with skilled framers commanding premium wages when available. Many projects face 2-3 month delays just waiting for framing crews.

Sustainability Mandates Oregon’s environmental consciousness isn’t just cultural – it’s increasingly regulatory. Waste reduction, energy performance, and sustainable building practices are becoming requirements, not preferences.

The Prefab Evolution: Beyond Cookie-Cutter Solutions

When most people search “Oregon prefab homes,” they encounter two unsatisfying options:

Smart Oregon builders are discovering a hybrid solution: prefab framing systems that provide factory precision and speed while maintaining complete design flexibility.

Get your free copy of The DIY Owner-Builder’s Step-by-Step Guide to Shell Completion — a simple, practical roadmap to help you plan, frame, and complete your home’s shell with confidence.

Enter your email to download and receive helpful tips, updates, and exclusive insights to keep your project on track.

The Problem: Oregon’s extended wet season exposes traditional framing to moisture for months, leading to dimensional instability, mold risks, and material degradation.

The Solution: Factory-manufactured wall panels and engineered floor systems arrive at your jobsite precision-built in controlled environments. Your structural shell goes up in days, not weeks, minimizing weather exposure and ensuring dimensional stability critical for Oregon’s high-performance building requirements.

The Problem: Finding skilled framers in Oregon often means 2-3 month waits and premium pricing, with no guarantee of quality or schedule adherence.

The Solution: Prefab framing systems reduce on-site framing labor requirements by up to 60%. Your crew focuses on assembly rather than complex layout and cutting, dramatically reducing dependency on scarce skilled framers while maintaining superior quality.

The Problem: Traditional construction generates 15-20% material waste, conflicting with Oregon’s sustainability mandates and increasing disposal costs.

The Solution: Factory manufacturing with optimized cutting reduces waste to 2-3%, while controlled production environments eliminate weather-damaged materials. This aligns perfectly with Oregon’s environmental expectations and regulatory trends.

The Problem: Oregon’s evolving energy codes demand superior building envelope performance, difficult to achieve consistently with traditional field framing.

The Solution: Factory-built wall panels create more consistent assemblies with superior thermal performance, providing the precision needed to meet Oregon’s energy efficiency standards reliably.

Green-R-Panel has developed prefab framing systems specifically designed for challenging climates like Oregon’s. Their comprehensive approach addresses every pain point Oregon builders face:

Interior and Exterior Wall Panels

Advanced Sheathing Options Oregon’s climate demands superior moisture management. Green-R-Panel offers ZIP sheathing upgrades and alternative materials designed for Pacific Northwest conditions.

I-Joist and Open Web Floor Systems

Custom Roof Truss Systems

Optional Upgrades for Oregon Conditions

EZ SIPS Insulation Systems Enhanced insulation packages using EPS insulation for superior thermal performance, ideal for Oregon’s energy efficiency requirements.

Advanced Panel Systems Interior panelization options for faster interior completion, particularly valuable during Oregon’s wet season when interior work becomes critical.

Urban Infill Development: Portland’s Prefab Revolution

Portland’s competitive infill market is driving rapid adoption of prefab framing systems. With tight lot constraints, neighbor relations concerns, and premium land costs, speed and predictability determine project success.

Key Benefits for Urban Developers:

Coastal Construction: Battling the Elements

Oregon’s coastal building market faces unique challenges from salt air, high winds, and extended moisture exposure. Prefab framing systems provide crucial advantages:

Weather-Independent Construction Factory manufacturing eliminates on-site weather delays, critical for coastal projects where weather windows are limited and unpredictable.

Quality Consistency Controlled manufacturing environments ensure dimensional stability and moisture content consistency impossible to achieve in coastal field conditions.

Oregon’s rural markets face the most severe skilled labor shortages and logistics challenges. Prefab framing systems bring factory precision to remote locations:

Reduced Labor Dependency with fewer available contractors in rural Oregon, prefab systems allow projects to proceed with smaller, less specialized crews.

Simplified Logistics structural shell components delivered in 1-2 loads reduce the complexity of managing multiple material deliveries to remote locations.

Portland Metro Market: With median construction costs exceeding $200 per square foot, the speed and quality advantages of prefab framing systems typically result in net positive ROI within the first project.

Rural Oregon Markets: Lower construction costs but severe labor shortages make prefab framing systems attractive for their labor-reduction benefits and schedule predictability.

Coastal Markets: Premium pricing and challenging weather conditions create strong value propositions for prefab framing systems despite higher material costs.

Oregon builders increasingly face clients who prioritize environmental responsibility. Prefab framing systems align perfectly with these values:

Waste Reduction

Factory manufacturing with optimized cutting patterns reduces construction waste by 75-80% compared to traditional methods, directly supporting Oregon’s waste reduction goals.

Carbon Footprint

Reduced construction timelines and fewer material deliveries lower transportation-related emissions, while efficient factory production reduces overall carbon footprint.

Resource Efficiency

Precision manufacturing maximizes lumber utilization, supporting responsible forest management practices important to Oregon clients.

Long-term Performance

Superior building envelope consistency supports better energy performance throughout the building’s life, aligning with Oregon’s long-term sustainability objectives.

The Green-R-Panel Implementation Process

Phase 1: Design Integration (3–4 weeks)

Submit architectural plans or select from our proven standard models. Green-R-Panel’s design team optimizes the framing system for Oregon-specific requirements.

Phase 2: Factory Production (4–6 weeks)

Your framing system is manufactured with AutoCAD precision in a controlled factory environment while your foundation work is underway, ensuring an efficient project timeline.

Phase 3: Coordinated Delivery

Structural shell components are delivered in 1–2 organized loads, scheduled to align with your construction progress and Oregon’s weather conditions.

Phase 4: Rapid Assembly (1–2 weeks)

With detailed assembly guidance, your local crew — even those new to prefab systems — can efficiently erect the structural shell, minimizing delays and keeping your project on schedule.

Proven Pacific Northwest Experience

Green-R-Panel understands the unique challenges of building in the Pacific Northwest, from moisture management to seismic requirements.

Comprehensive Solutions

Rather than piecemeal suppliers, Green-R-Panel provides structural shell systems with single-source responsibility.

Engineering Excellence

Floor systems and roof trusses include sealed engineering drawings that meet Oregon’s specific structural requirements, while wall panels provide precision manufacturing that supports superior building envelope performance.

Practical Implementation

Systems designed for real-world Oregon construction challenges, not theoretical perfection.

Oregon’s construction industry is evolving rapidly in response to regulatory changes, environmental expectations, and market pressures. Builders who adapt early gain sustainable competitive advantages.

Regulatory Trends

Oregon’s building codes will continue emphasizing energy efficiency, waste reduction, and environmental performance – all areas where prefab framing systems provide advantages.

Market Evolution

Client expectations for predictable timelines, superior quality, and environmental responsibility favor construction methods that deliver consistent results.

Labor Market Reality

Oregon’s skilled labor shortage is structural, not cyclical. Successful builders are reducing their dependency on scarce skilled framers now, not hoping conditions improve.

Trusted by do-it-yourself owner-builders and professionals for 20+ years—build smarter with Green-R-Panel’s proven support.

Strong Candidates for Prefab Framing Systems

You Should Prioritize Prefab Framing If:

Traditional Methods Might Work If:

Market-Specific Considerations

Portland Metro: Speed and quality premiums strongly favor prefab framing systems

Coastal Oregon: Weather challenges make prefab systems nearly essential

Rural Oregon: Labor scarcity creates strong value proposition

Central Oregon: Weather variability and growth pressures support prefab adoption