Last Updated: October 2025

While the rest of the country deals with typical construction challenges, Arizona builders face a perfect storm of obstacles. If you’ve been dreaming of building your own home in Arizona, you already know how challenging the market conditions have become. Arizona’s housing market remains supply constrained, with demand still outpacing the supply of affordable housing across the state. More than 55,000 new housing units have been permitted in Arizona in 2024, yet this barely scratches the surface of what’s needed to address the ongoing housing crisis.

The financial pressure is undeniable. The average home costs 55.2% more today than it did at the end of 2019, and the cost to build a house in Arizona ranges from $150 to $280+ per sq ft, with total costs averaging $400,000 to $1,100,000 before land acquisition or site preparation. In Phoenix and Tucson metro areas, extreme summer heat can halt construction for hours each day. Monsoon seasons bring unexpected delays. And across the state, finding and retaining skilled framing crews has become one of the biggest obstacles for anyone trying to break ground.

For many prospective homeowners facing these challenges, prefabricated housing seems like an attractive solution. Prefab promises speed, cost predictability, and relief from Arizona’s brutal construction conditions—but not all prefab approaches deliver equal results. Beyond the standard “modular box delivered on a flatbed” that most people envision, there’s a more flexible alternative that provides prefab efficiency while preserving complete design freedom: prefab framing systems.

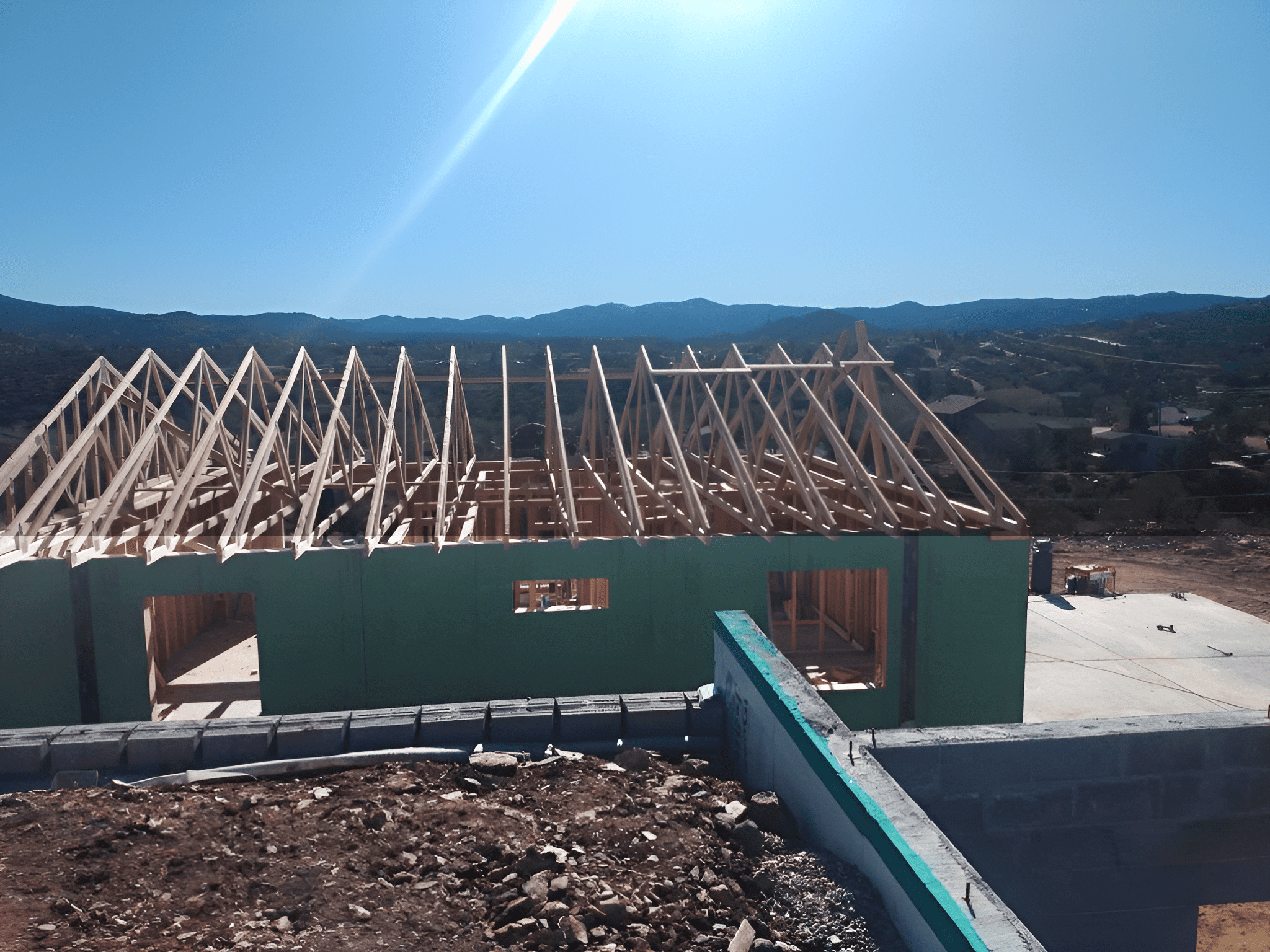

With Green-R-Panel, the structural foundation is handled in advance—your home’s complete shell (floors, walls, and roof trusses) is precision-manufactured in climate-controlled facilities, delivered to your site in sequential build order, and ready for rapid assembly—allowing you to build smarter, faster, and with significantly less exposure to Arizona’s challenging climate.

Exploring Arizona prefab homes, you’ve likely encountered traditional modular and manufactured housing options that come with substantial drawbacks—limited customization options, premium pricing per square foot, and rigid site preparation demands that can completely derail your construction schedule and budget.

But what if there was a superior approach? A solution that delivers prefab construction’s speed and precision advantages without the design restrictions or inflated costs?

That’s where prefab framing systems revolutionize the game—the innovative methodology that’s reshaping how custom homes, spec builds, and owner-builder projects get executed throughout Arizona.

Arizona’s unique construction environment creates specific challenges that make conventional prefab homes less appealing than they initially seem:

Design Restrictions: Most prefab manufacturers provide limited floor plan selections with minimal customization capabilities. Want to modify room layouts or incorporate custom architectural features? You’ll face expensive change orders or outright refusal.

Site Preparation Demands: Traditional prefab homes demand extremely precise foundation work and extensive site preparation. Even minor deviations from exact specifications can postpone delivery and installation for weeks or months.

Hidden Cost Escalation: While prefab homes advertise appealing base pricing, final costs frequently exceed traditional construction when factoring in site preparation, specialized delivery services, crane rentals, and premiums for any modifications.

Limited Installer Network: Locating qualified installation teams for traditional prefab systems in Arizona proves challenging, particularly in rural areas where many people prefer to build.

Prefab framing systems eliminate these problems by providing the essential structural elements—wall panels, floor systems, and roof trusses—as precision-manufactured components and engineered assemblies, while preserving complete design flexibility and compatibility with conventional construction methods.

Here’s the process: Rather than delivering a finished prefab home, Green-R-Panel manufactures your home’s structural shell components in controlled factory conditions, then ships them to your jobsite as pre-assembled interior and exterior wall panels plus engineered floor and roof systems ready for efficient installation.

Precision-Manufactured Wall Panels

Engineered I-Joist/Open Web Truss Floor Systems

Engineered Roof Truss System

Get your free copy of The DIY Owner-Builder’s Step-by-Step Guide to Shell Completion — a simple, practical roadmap to help you plan, frame, and complete your home’s shell with confidence.

Enter your email to download and receive helpful tips, updates, and exclusive insights to keep your project on track.

Traditional stick-framing requires 3-8 weeks just for structural shell completion, assuming favorable weather conditions. Prefab framing systems compress this timeline to 1-3 weeks for most residential projects. Your construction team spends dramatically less time measuring, cutting, and assembling components, enabling faster progression to roof installation and interior finish work.

Arizona-Specific Advantage: Complete structural framing and achieve weatherproofing weeks sooner, minimizing exposure to monsoon delays and extreme temperature work restrictions.

With skilled labor shortages impacting construction statewide, prefab framing systems directly address this challenge. Wall panels arrive pre-assembled and installation-ready, reducing skilled labor requirements by up to 60% during the framing phase.

Owner-Builder Advantage: For those planning owner-built projects, prefab framing systems dramatically simplify the structural construction phase. Detailed assembly instructions and precision-manufactured components reduce dependence on increasingly scarce framing subcontractors.

Factory-controlled manufacturing eliminates variables that compromise jobsite construction—extreme weather exposure, material storage complications, and inconsistent workmanship. Computer-controlled cutting and automated assembly ensure every component meets exact specifications.

Finish Work Benefits: Consistent dimensional tolerances enable smooth drywall, flooring, and trim installation without delays and additional costs associated with correcting framing irregularities.

Controlled environment manufacturing virtually eliminates material waste. No lumber exposure to monsoon moisture, no jobsite theft concerns, and no material over-ordering for contingencies.

Budget Predictability: Material costs are locked during manufacturing, protecting you from lumber price volatility that can add thousands to traditional builds.

Arizona’s owner-builder community is recognizing that prefab framing systems resolve their most significant challenges:

For builders specializing in custom residential projects, prefab framing systems integrate seamlessly with unique designs while improving profit margins:

Multi-unit developments and townhome projects benefit from repeatability and logistical advantages:

While every project presents unique variables, most builders realize significant cost advantages with prefab framing systems:

Labor Savings: 60% reduction in framing labor typically saves $12,000-$18,000 on a 2,000 sq ft home

Material Efficiency: Controlled manufacturing reduces waste by 15-20%, saving $3,000-$5,000 in materials

Time Savings: 2-4 week timeline reduction saves carrying costs and accelerates revenue generation

Quality Improvements: Reduced callbacks and warranty claims improve long-term profitability

Ready to evaluate whether prefab framing systems align with your Arizona building project? Here’s essential information:

Project Types That Benefit Most:

Required Information:

Timeline Expectations:

Arizona’s construction market faces unprecedented demand, persistent skilled labor shortages, and ongoing material cost volatility. Prefab framing systems address all three challenges while delivering superior construction outcomes.

Whether you’re an owner-builder frustrated with coordinating multiple subcontractors, a custom builder seeking to improve margins and minimize risk, or a small developer pursuing competitive advantages, prefab framing systems provide a proven pathway to better results.

Organizations that adopt these advanced construction methodologies now will dominate their markets while traditional builders continue struggling with the same persistent problems: unpredictable schedules, quality inconsistencies, and escalating labor costs.

Arizona prefab homes don’t require compromising your vision. With prefab framing systems, you achieve factory construction’s speed and precision with complete design flexibility and cost control.

Contact Green-R-Panel today to discuss your project requirements and discover how prefab framing systems can transform your next Arizona build. From initial consultation through final delivery, our team provides the expertise and support necessary for project success.

Get started with a project consultation and see exactly how prefab framing systems can optimize your Arizona building project.

Trusted by do-it-yourself owner-builders and professionals for 17+ years—build smarter with Green-R-Panel’s proven support.