Know the Difference Before You Build

Introduction

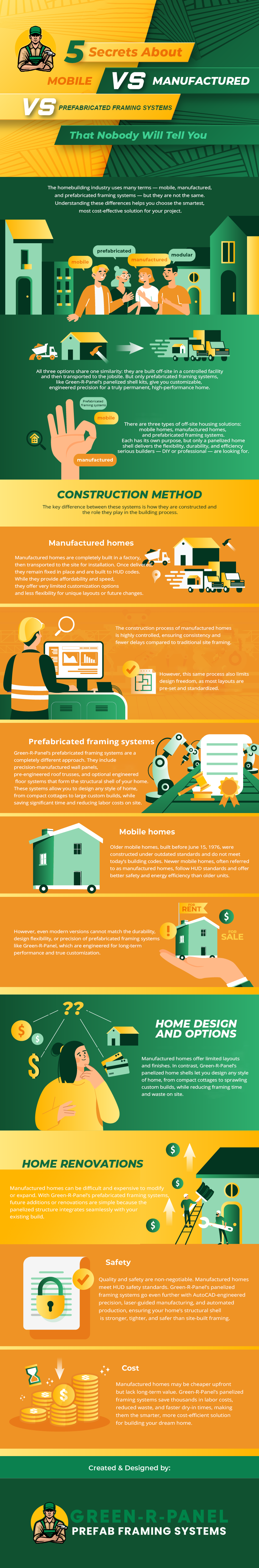

When researching your dream home, you’ll see many terms like mobile homes, manufactured homes, modular homes, and panelized building systems. Although they sound similar, each refers to a very different construction method.

Knowing these differences helps you make smarter, more cost-effective decisions—and avoid expensive mistakes later.

Secret #1: Mobile Homes Are Not the Same as Modern Manufactured Homes

True “mobile homes” existed before 1976 and followed outdated, non-engineered standards. After that, the industry introduced manufactured homes built under the federal HUD Code. These homes come almost move-in ready, yet they still differ from site-built or panelized homes.

Even the most modern manufactured homes follow standardized floor plans and fixed designs. They offer little room for structural or layout customization. As a result, your design options are often limited before construction even begins.

Secret #2: Manufactured Homes Are Finished—but Inflexible

Manufactured homes leave the factory with walls, floors, roofs, plumbing, electrical wiring, and finishes already installed. While that setup may seem fast, it limits your ability to personalize your home later.

- Layouts remain fixed and rarely change

- Material and finish choices are restricted to factory options

In short, you gain convenience at the start but lose flexibility over time. For anyone who values design freedom, that trade-off can be frustrating.

Secret #3: Panelized Systems Give You the Shell—Not the Finish

Green-R-Panel’s panelized building systems focus on what matters most—the structural shell. This includes prefabricated wall panels, engineered floor systems, and roof trusses. Skilled technicians manufacture each component in a controlled environment and ship them flat-packed directly to your jobsite.

This approach gives you multiple advantages:

- Full design freedom for layout, finishes, and interiors

- Faster framing and lower labor costs

- A stronger, more energy-efficient building envelope

- Freedom to select your own mechanical, electrical, and interior systems

As a result, you enjoy the efficiency of prefabrication without losing creative control. It’s the best of both worlds—speed and customization.

Secret #4: Renovations Are Nearly Impossible on Manufactured Homes

Manufactured homes come as sealed units with plumbing, wiring, and finishes built in. Because of that, expanding or remodeling later becomes complicated and expensive.

By contrast, panelized building systems allow you to adapt your home over time. You can add a room, finish a basement, or upgrade systems easily. The structure uses the same framing techniques as a conventional home—only faster and more precise. Therefore, you maintain flexibility long after move-in day.

Secret #5: Panelized Homes Offer Better Long-Term Value

While manufactured homes might look cheaper upfront, panelized homes consistently deliver better long-term value. Here’s why:

- Lower framing costs—you save up to 60% on labor

- Less material waste—factory precision reduces scrap

- Faster dry-in times—you cut financing and weather delays

- Higher resale appeal—panelized homes meet local codes and look like custom builds

Whether you’re an owner-builder, a custom home contractor, or a small developer, the panelized approach offers a smart balance of cost, speed, and design freedom.

Build Smarter with Green-R-Panel

When comparing mobile, manufactured, and modular homes, keep this in mind: those homes arrive finished but inflexible. Panelized building systems, on the other hand, deliver only the structural shell—the foundation of your custom design. You decide the rest.

With Green-R-Panel, you get precision-engineered components that let you build faster and smarter while maintaining creative control. Choose a system that supports your vision instead of limiting it.

📞 Call us today at 1-800-871-7089

📧 Or email us at [email protected]

Comments are closed