Last updated: September 2025

If you’re a DIY owner-builder in Maryland, you’re navigating a housing market filled with both obstacles and opportunity. Although active home listings have recently surged—up nearly 48% year-over-year—many residents still struggle with affordability and sluggish construction timelines. In fact, University of Maryland researchers warn that lagging construction and restrictive zoning are driving up home prices and pushing residents out of homeownership.

Compounding the challenge, the state faces a substantial housing gap: experts estimate that nearly 600,000 new homes will be needed by 2045, alongside a rental shortfall of 300,000 units—disproportionately affecting low-income households. In response, the Moore administration has set a goal to add 96,000 housing units and is advancing zoning reform and streamlined approvals to ease the crisis. For example, Montgomery County recently updated its zoning code to allow duplexes or triplexes on existing single-family lots—a promising step toward expanding affordable “missing middle” housing.

As an owner-builder, this uncertain landscape can leave you stuck between rising costs, slow permits, weather delays, and shrinking timelines. So, do you wrestle with traditional construction—or explore a smarter path?

That’s where “prefab homes” come in. This increasingly popular approach delivers on a powerful promise: build faster, more predictably, and more affordably. However, “prefab” doesn’t always mean a fully finished home dropped on your lot. Instead, a growing number of savvy DIYers in Maryland are turning to a more adaptable option: prefab framing systems.

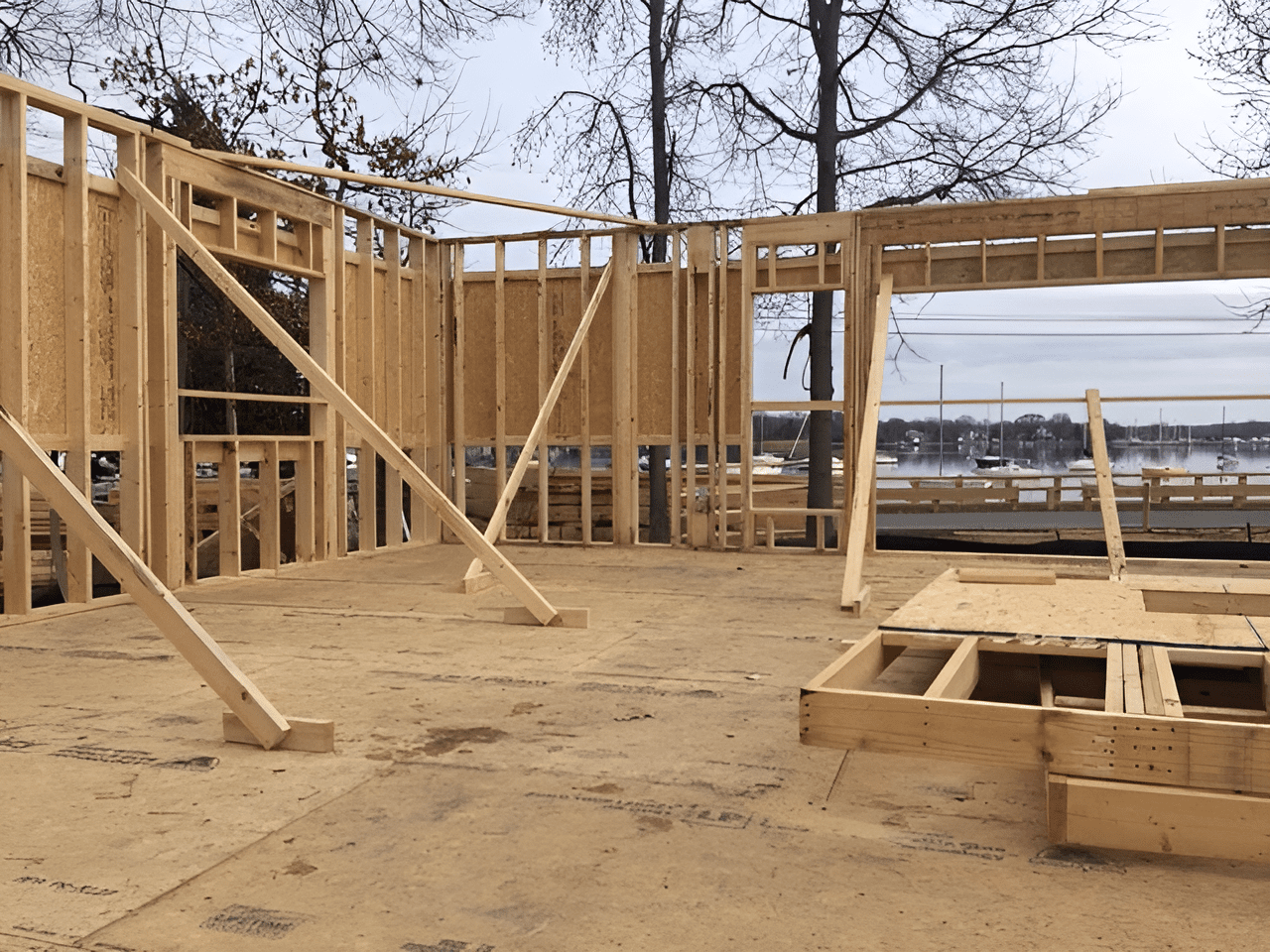

With Green-R-Panel, you receive factory-manufactured wall, floor, and roof panels—precision-cut and delivered to your site in a clear, organized sequence. Because everything arrives ready to assemble, you can erect the weather-tight shell in days, not weeks. From there, you take the reins: adding your own finishes, fixtures, and custom design details on-site. In short, it’s a hybrid method that gives you speed and structural integrity—without sacrificing control or creativity.

Ultimately, if your goal is to build on your own schedule, avoid cost overruns, and keep your vision intact, prefab framing isn’t just a trend. For Maryland’s determined DIY builders, it’s the strategic shift that turns housing pressure into homeownership opportunity.

When most people hear “prefab homes,” they imagine factory-built boxes or repetitive, cookie-cutter designs. Prefab framing systems are completely different. They’re precision-engineered building components—custom-manufactured wall panels, floor systems, and roof trusses—built to your exact plans and delivered ready for fast, accurate assembly on-site.

Here’s what you actually get in 2025:

• Precision-manufactured wall panels (interior and exterior) built to your architectural specifications

• Engineered I-joist or open web truss floor systems with sealed structural drawings

• Engineered roof truss systems designed and stamped to meet your project’s load requirements

• AutoCAD-based layouts and shop drawings that ensure every component fits perfectly the first time

The result? You’re not buying a “prefab home” — you’re investing in a smarter, faster, and more cost-efficient way to build the custom home you actually want.

Maryland builders are facing a tougher market than ever, with rising labor shortages, escalating costs, and unpredictable weather patterns putting traditional stick framing under serious pressure.

Labor Crisis by the Numbers (2025):

• 71% of Maryland contractors report difficulty finding skilled framing labor

• Framing crew rates have risen an average of 34% since 2022

• Weather-related delays now add an average of 14 lost days per project statewide

Material Waste Reality:

• Traditional stick framing still wastes 15–22% of lumber and sheathing materials

• Jobsite theft and shrinkage continue to impact over 70% of Maryland projects

• Weather exposure and moisture damage now average $3,800 in losses per project

Quality Control Challenges:

• Nearly 45% of new homebuyers report minor or major framing-related issues within the first year

• Rework and correction costs consume 8–13% of total framing budgets

• Moisture-related structural issues affect 1 in 5 new homes across Maryland coastal and inland zones

These aren’t just statistics—they’re real challenges that are driving both professional builders and DIY owner-builders to adopt panelized and prefab framing systems as their go-to solution.

Prefab framing means fewer delays, higher precision, reduced waste, and faster dry-in—exactly what Maryland’s builders need in 2025 and beyond.

Speed That Actually Matters

Traditional framing for a 2,500 sq ft home in Maryland averages 3-4 weeks with weather delays. Prefab framing systems can cut this to 1-2 weeks for realistic shell completion.

Real Time Savings:

With Maryland’s skilled labor shortage, prefab framing systems reduce dependence on hard-to-find experienced framers by up to 60%.

How It Works:

Quality You Can Measure

Factory-controlled manufacturing delivers consistency that’s impossible with site-built framing.

Precision Manufacturing Benefits:

Cost Control That Works

While upfront material costs may be slightly higher, total project costs typically decrease through:

Get your free copy of The DIY Owner-Builder’s Step-by-Step Guide to Shell Completion — a simple, practical roadmap to help you plan, frame, and complete your home’s shell with confidence.

Enter your email to download and receive helpful tips, updates, and exclusive insights to keep your project on track.

Why They Choose Prefab Framing:

Real Benefits:

Why They’re Making the Switch:

The Competitive Advantage:

Precision-Manufactured Wall Panels

Standard Specifications:

Two Options Based on Your Foundation:

Professional Engineering Included:

Optional Upgrades Available

Maryland’s climate creates unique challenges for traditional construction:

Prefab framing systems minimize weather exposure, keeping projects on schedule regardless of Maryland’s weather patterns.

Maryland’s building codes are increasingly complex, especially for:

Factory-manufactured components with engineered floor and roof systems help ensure your project meets Maryland’s evolving building standards.

With Maryland’s construction workforce aging (average framer age: 47), prefab framing systems offer a sustainable solution:

Project: 3,200 sq ft custom home with complex roofline

Results:

Project: 8-unit townhome cluster

Results:

Project: 2,800 sq ft family home with walkout basement

Results:

Key Advantage of Prefab Framing Systems: You get the speed and precision benefits of prefab manufacturing while maintaining complete control over design, finishes, timeline, and local contractor relationships.

Best choice depends on your priorities: speed vs. control, standardization vs. customization, and how much involvement you want in the building process.

Step 1: Plan Review and Consultation

Step 2: Custom AutoCAD Design

Step 3: Factory Manufacturing

Step 4: Delivery and Installation

Perfect Fit Projects:

Consider Other Options If:

Trusted by do-it-yourself owner-builders and professionals for 17+ years—build smarter with Green-R-Panel’s proven support.

Maryland’s construction landscape is changing rapidly. Rising labor costs, material shortages, and weather delays are making traditional construction methods increasingly risky and expensive.

Prefab framing systems offer a proven solution that’s already working for hundreds of Maryland builders:

The question isn’t whether prefab framing systems work – it’s whether you can afford to keep building the old way while your competition gains every advantage that modern manufacturing offers.