The Future of Homebuilding Is Here

Introduction

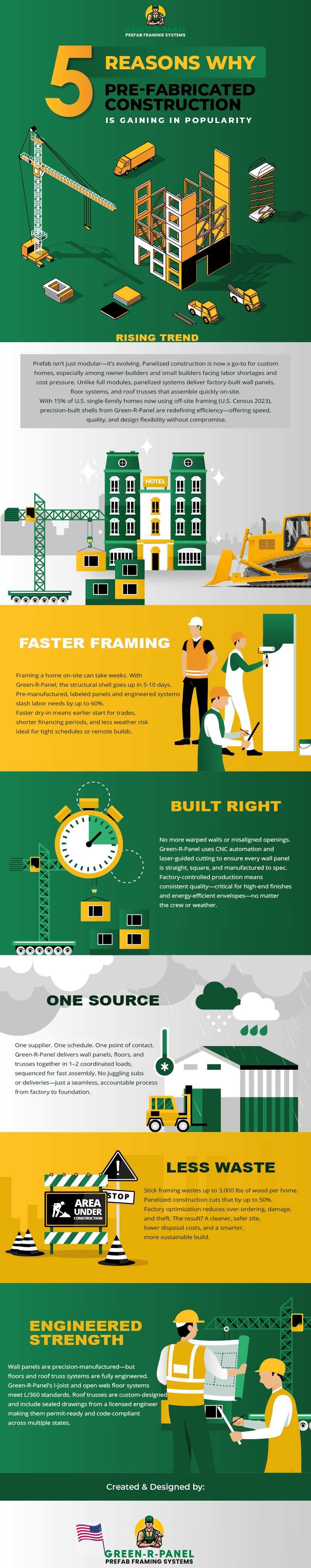

Prefab construction is no longer a niche, panelized building systems are surging in popularity —it’s the future of smarter homebuilding. Unlike modular homes that arrive as full box units, panelized building systems deliver precision-built prefabricated wall panels, engineered floor systems, and roof trusses directly to your site.

The result? Faster construction, superior quality, and greater design freedom for owner-builders, custom contractors, and small developers.

Reason 1: Rising Trend in Modern Construction

Off-site construction is growing rapidly across the U.S. In fact, over 15% of new single-family homes now use some form of prefabrication (U.S. Census 2023).

Green-R-Panel’s panelized building systems meet the demand for efficiency, speed, and quality—without sacrificing flexibility in design. Whether you’re building a custom cottage, a modern two-story, or a multi-unit project, panelized framing offers the advantages of factory precision combined with on-site customization.

Reason 2: Faster Framing, Shorter Timelines

Traditional stick framing can take weeks. With Green-R-Panel, your home’s structural shell—including prefabricated wall panels, engineered floor systems, and roof trusses—is delivered pre-manufactured, labeled, and ready for rapid assembly.

- Typical dry-in time: just 5–10 days

- Save up to 60% in on-site labor hours

- Reduce weather delays and financing costs

- Ideal for tight schedules or remote building locations

Reason 3: Built Right—Factory Precision & Quality Control

Quality control is where panelized systems shine. Every component is manufactured using AutoCAD precision, CNC automation, and laser-guided cutting to ensure square, straight walls and perfectly engineered fits.

This factory-controlled process eliminates:

- Warped studs

- Misaligned openings

- On-site errors caused by inconsistent labor

The result: a stronger, tighter, and more energy-efficient building envelope—critical for long-term durability and high-end finishes.

Reason 4: One Source for Your Entire Structural Shell

With Green-R-Panel, you get one supplier, one schedule, and one point of contact. Prefabricated wall panels, floor systems, and roof trusses arrive together in 1–2 coordinated loads, sequenced for fast assembly.

No juggling multiple suppliers, no missed deliveries—just a seamless, accountable process from factory to foundation.

Reason 5: Less Waste, Greater Sustainability

Stick framing can waste up to 8,000 lbs. of lumber on a single home. Panelized construction cuts that waste in half.

Factory precision ensures efficient use of materials, reducing over-ordering, jobsite scraps, and disposal costs. The benefits are clear:

- Lower material expenses

- Cleaner, safer jobsites

- A smarter, more sustainable way to build

Engineered Strength for Code Compliance

Unlike site-built framing, Green-R-Panel’s engineered floor systems and roof trusses are fully engineered to meet or exceed building codes. Each system comes with sealed structural drawings, giving you confidence that your home is permit-ready and code-compliant across multiple states.

This means your project isn’t just faster—it’s stronger, smarter, and built to last.

Build Smarter with Green-R-Panel

Prefab is the future, and panelized building systems are leading the way. By combining prefabricated wall panels, engineered floor systems, and roof trusses into one integrated package, Green-R-Panel makes homebuilding faster, more affordable, and more efficient than ever.

📞 Call 1-800-871-7089 or 📧 email [email protected] today to learn more about pricing, design support, and complete building system details.

Comments are closed